From an article at nanowerknews.com:

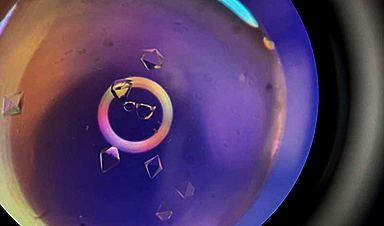

Three-dimensional printing allows extremely small and complex structures to be made even in small series. A method developed at the KIT for the first time allows also glass to be used for this technique.

As a consequence of the properties of glass, such as transparency, thermal stability and resistance to acids, the use of this material in 3D-printing opens up manifold new applications in production and research, such as optics, data transmission, and biotechnology.

The process is published in Nature (“Three-dimensional printing of transparent fused silica glass“) and also presented at the Hanover Fair.

Recent News

Breakthrough in Antimicrobial Technology with Cinnamon-Based Nanokiller

The need for innovative antimicrobial agents has become increasingly urgent due to the rise of antibiotic-resistant pathogens and the persistent threat of infections acquired during hospital stays. Traditional antibiotics [...]

The Silent Battle Within: How Your Organs Choose Between Mom and Dad’s Genes

Research reveals that selective expression of maternal or paternal X chromosomes varies by organ, driven by cellular competition. A new study published today (July 26) in Nature Genetics by the Lymphoid [...]

Study identifies genes increasing risk of severe COVID-19

Whether or not a person becomes seriously ill with COVID-19 depends, among other things, on genetic factors. With this in mind, researchers from the University Hospital Bonn (UKB) and [...]

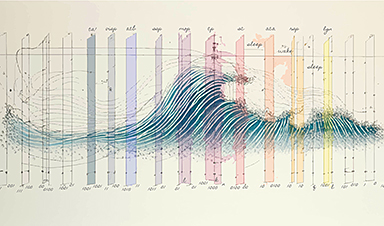

Small regions of the brain can take micro-naps while the rest of the brain is awake and vice versa

Sleep and wake: They're totally distinct states of being that define the boundaries of our daily lives. For years, scientists have measured the difference between these instinctual brain processes [...]

Redefining Consciousness: Small Regions of the Brain Can Take Micro-Naps While the Rest of the Brain Is Awake

The study broadly reveals how fast brain waves, previously overlooked, establish fundamental patterns of sleep and wakefulness. Scientists have developed a new method to analyze sleep and wake states [...]

AI Reveals Health Secrets Through Facial Temperature Mapping

Researchers have found that different facial temperatures correlate with chronic illnesses like diabetes and high blood pressure, and these can be detected using AI with thermal cameras. They highlight [...]

Breakthrough in aging research: Blocking IL-11 extends lifespan and improves health in mice

In a recent study published in the journal Nature, a team of researchers used murine models and various pharmacological and genetic approaches to examine whether pro-inflammatory signaling involving interleukin (IL)-11, [...]

Promise for a universal influenza vaccine: Scientists validate theory using 1918 flu virus

New research led by Oregon Health & Science University reveals a promising approach to developing a universal influenza vaccine—a so-called "one and done" vaccine that confers lifetime immunity against [...]

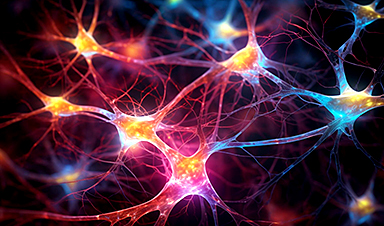

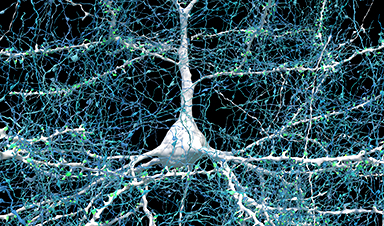

New Projects Aim To Pioneer the Future of Neuroscience

One study will investigate the alterations in brain activity at the cellular level caused by psilocybin, the psychoactive substance found in “magic mushrooms.” How do neurons respond to the [...]

Decoding the Decline: Scientific Insights Into Long COVID’s Retreat

Research indicates a significant reduction in long COVID risk, largely due to vaccination and the virus’s evolution. The study analyzes data from over 441,000 veterans, showing lower rates of long [...]

Silicon Transformed: A Breakthrough in Laser Nanofabrication

A new method enables precise nanofabrication inside silicon using spatial light modulation and laser pulses, creating advanced nanostructures for potential use in electronics and photonics. Silicon, the cornerstone of [...]

Caught in the actinium: New research could help design better cancer treatments

The element actinium was first discovered at the turn of the 20th century, but even now, nearly 125 years later, researchers still don't have a good grasp on the [...]

Innovative Light-Controlled Drugs Could Revolutionize Neuropathic Pain Treatment

A team of researchers from the Institute for Bioengineering of Catalonia (IBEC) has developed light-activated derivatives of the anti-epileptic drug carbamazepine to treat neuropathic pain. Light can be harnessed [...]

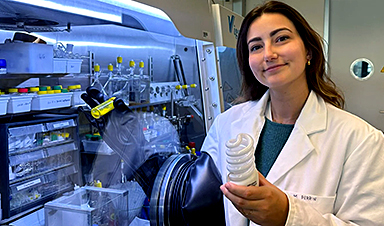

Green Gold: Turning E-Waste Into a Treasure Trove of Rare Earth Metals

Scientists are developing a process inspired by nature that efficiently recovers europium from old fluorescent lamps. The approach could lead to the long-awaited recycling of rare earth metals. A [...]

Cambridge Study: AI Chatbots Have an “Empathy Gap,” and It Could Be Dangerous

A new study suggests a framework for “Child Safe AI” in response to recent incidents showing that many children perceive chatbots as quasi-human and reliable. A study has indicated [...]

Nanoparticle-based delivery system could offer treatment for diabetics with rare insulin allergy

Up to 3% of people with diabetes have an allergic reaction to insulin. A team at Forschungszentrum Jülich has now studied a method that could be used to deliver [...]

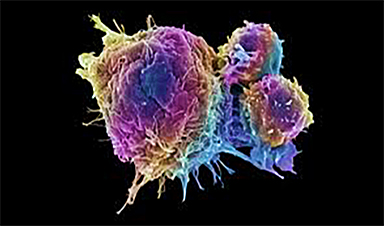

Nanorobot kills cancer cells in mice with hidden weapon

Researchers at Karolinska Institutet in Sweden have developed nanorobots that kill cancer cells in mice. The robot's weapon is hidden in a nanostructure and is exposed only in the [...]

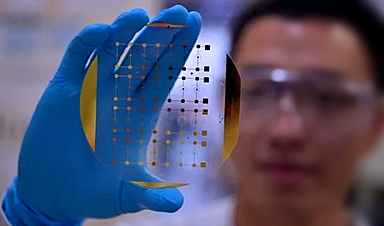

Novel device uses a simple blood test to detect early stage lung cancer

Dr Richard Lobb and Quan Zhou from UQ’s Australian Institute for Bioengineering and Nanotechnology said the diagnostic device could help patients begin treatment and get ahead of the disease before it spreads. "Lung cancer [...]

Reevaluating Drug Safety: Real-World Data Challenges Old Methods

A University of Pennsylvania study suggests that real-world data, rather than case reports, should be used to assess medication-related liver toxicity more accurately, potentially leading to better patient monitoring and safety. [...]

Scientists Have Identified Over 5000 High-Risk Cancer Gene Variants

Researchers have pinpointed specific variants in a gene that significantly raise the likelihood of developing various cancer types. This discovery has the potential to enhance early detection and facilitate [...]

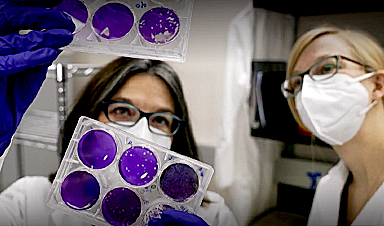

Breast cancer vaccine study begins with first patient

An innovative study of a breast cancer vaccine is officially underway, as University of Pittsburgh Medical Center announced on June 20 that the first participant had received her full [...]

Ultra-detailed brain map shows neurons that encode words’ meaning

By eavesdropping on the brains of living people, scientists have created the highest-resolution map yet of the neurons that encode the meanings of various words1. The results hint that, across [...]

Re-engineering cancerous tumors to self-destruct and kill drug-resistant cells

Treating cancer can sometimes feel like a game of Whac-A-Mole. The disease can become resistant to treatment, and clinicians never know when, where and what resistance might emerge, leaving [...]

Research could help drug developers improve the safety profiles of medications

Research from the University of British Columbia, MIT, and the University of Michigan could help drug developers improve the safety profiles of medications and reduce side effects. Chemists have [...]

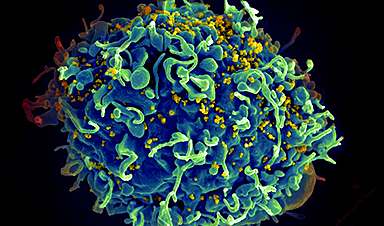

New lab test to detect persistent HIV strains in Africa may aid search for cure

A multinational team led by Weill Cornell Medicine investigators developed a test that will help measure the persistence of HIV in people affected by viral strains found predominantly [...]

Nasal COVID-19 Vaccine Secures Federal Funding for Groundbreaking Clinical Trial

The trial will evaluate the effectiveness and safety of a new vaccine compared to an FDA-approved mRNA vaccine. University of Georgia-based startup CyanVac LLC has received federal funding to conduct a [...]

Scientists closing in on why some people never get COVID.

Early on in the pandemic, in 2021, Hugh Potter ate dinner and watched TV next to his wife while she coughed violently from COVID-19, yet he never even sniffled. [...]

Help or hindrance? ER robots have potential to aid health care workers

Amid the unpredictability and occasional chaos of emergency rooms, a robot has the potential to assist health care workers and support clinical teamwork, Cornell and Michigan State University [...]

For tendon healing: Nanoparticles for precision drug delivery

Harnessing nanoparticles to deliver drugs precisely to a surgically repaired tendon is a promising new approach that reduced scar tissue formation and improved mechanical function. Researchers' success in pinpointing [...]

Gold nanoparticles kill cancer – but not as thought

Gold particles of the size of billionths of a meter are lethal to cancer cells. This fact has been known for a long time, as has a simple correlation: [...]

Beyond Einstein: Exploring Spacetime Through Finsler Geometry

Investigations into gravitational waves and their relationship with Finsler geometry are providing new insights into spacetime, suggesting ways to harmonize relativity and quantum mechanics. When speaking of our universe, it’s often [...]

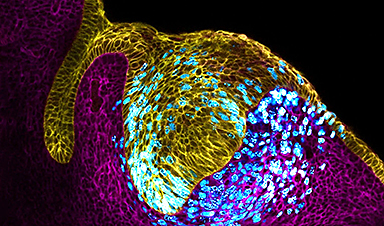

Revolutionizing Regeneration: Rat Stem Cells Restore Mouse Brain Circuits

Research teams have successfully regenerated mouse brain circuits using rat stem cells, showcasing a new method for restoring brain function and studying interspecies brain development. These findings open up [...]

Meet the Virus-Killing Plastic That’s Changing the COVID Game

Studies at the University of Jyväskylä in Finland show that resin-treated plastics can quickly deactivate viruses, part of a larger effort under the BIOPROT project to develop bio-based antiviral [...]

Study shows familiarity with gene editing increases approval of the safety of GMOs

The more that people know about gene editing, the more likely they are to feel it is safe to use in agriculture and medicine, according to a survey of [...]

Study finds connection between cannabis use and increased risk of severe COVID-19

As the deadly disease that came to be known as COVID-19 started spreading in late 2019, scientists rushed to answer a critical question: Who is most at risk? They [...]

New Bioplastic Straw Degrades Even Faster in the Ocean Than Paper

Researchers determine the lifetimes of commercial drinking straws in the coastal ocean and develop a prototype bioplastic straw that degrades even faster than paper. A WHOI study has shown [...]

Scientists Discover Unexpected Importance of “Time Cells” for Complex Learning

Researchers at the University of Utah Health found that “time cells” in mice adapt to learning timed tasks, a discovery that could aid early Alzheimer’s detection by monitoring changes in a [...]

Mussel-Inspired Technique Paves Way for Efficient Nanoparticle Assembly

Nanoscale materials offer remarkable chemical and physical properties that transform theoretical applications, like single-molecule sensing and minimally invasive photothermal therapy, into practical realities. The unparalleled features of nanoparticles make [...]

All the Data on Earth Can Fit in a Cup Full of DNA – MIT’s Jurassic Park-Inspired Project

Since the early days of computer science, scientists have been exploring the idea of using DNA to store data. MIT has developed an amber-like polymer that can keep DNA [...]

Novel approach enables bidirectional brain-computer interface functionality

Brain-computer interfaces, or BCIs, hold immense potential for individuals with a wide range of neurological conditions, but the road to implementation is long and nuanced for both the invasive [...]

Decoding Mental Health With Advanced Brain Gene Maps

Groundbreaking maps reveal the complex gene regulation in brains with and without mental disorders, enhancing the understanding of mental illnesses and potential treatments. A consortium of researchers has produced [...]

Biological Differences in How Men and Women Perceive Pain Discovered

Researchers have discovered sex-specific differences in the nerve cells that generate pain, paving the way for personalized pain management treatments based on patient sex. Research indicates that men and [...]

Scientists May Have Discovered the First Sign of Autism: An Unusually Large Brain

Researchers at the University of California San Diego discovered that an unusually large brain could be the first sign of autism, potentially detectable in as early as the first [...]

$100M Funding – Phase 3 trial of first oral disease-modifying therapy for Alzheimer’s.

Clinical-stage biotech Alzheon has completed a $100 million Series E financing round to advance the development and commercialization of its oral drug for Alzheimer’s disease. The drug, called ALZ-801 (valiltramiprosate), is [...]

‘Dual mutant’ seasonal flu virus could make some treatments ineffective

Two human cases of "dual mutant" strains of H1N1 flu have been reported by U.S. health officials. Unfortunately, the genetic changes appear to render the leading flu antiviral, Tamiflu, less effective, [...]

Mutation Mystery Solved: Why Lung Cancer Treatments Often Fail in Non-Smokers

Researchers have discovered the reason why targeted treatment for non-small cell lung cancer fails to work for some patients, particularly those who have never smoked. The study shows that [...]

Innovative blood test boosts accuracy of lung cancer screening

In a recent study published in Cancer Discovery, researchers developed and validated a blood-based, cell-free deoxyribonucleic acid (cfDNA) fragmentome assay for lung cancer detection, which, if the results were positive, [...]

Researchers Uncover Significant Cognitive Differences Between Male and Female Brains

Research from Weill Cornell Medicine reveals that astrocyte receptors impact cognitive functions differently in males and females, suggesting a need for sex-specific approaches in developing treatments targeting these brain [...]

Columbia Scientists Unravel a 15-Year Mistake in Stem Cell Research

Columbia University’s research has uncovered a longstanding error in identifying gut stem cells, finding the true stem cells in a different site, which could revolutionize regenerative medicine by applying [...]

COVID-19 Triggers Lethal Lung Disease in Previously Unaffected Populations

Researchers discovered that during the COVID-19 pandemic, there was a surge in a rare autoimmune disease among previously unaffected demographic groups, leading to the deaths of nine patients. The disease is [...]

Spicing Up Pathogen Defense: Scientists Transform Cinnamon Into Nanotech Antimicrobials

Cinnamon oil-based nanodevice effectively targets key pathogens, with potential uses in healthcare and food safety A team of researchers from the Universitat Politècnica de València (UPV) and the CIBER [...]

High Excess Death Rates 3 Years Running Since COVID – “Serious Cause for Concern”

Despite containment and COVID-19 vaccines; “serious cause for concern,” say researchers. A study highlights persistent high excess death rates in the West from 2020 to 2022, despite COVID-19 measures and vaccines. [...]

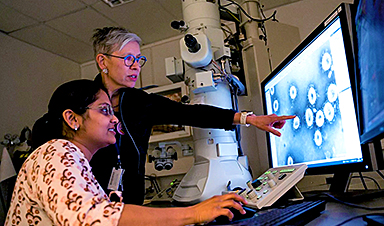

Super-resolution microscopy provides a nano-scale look

A new, nano-scale look at how the SARS-CoV-2 virus replicates in cells may offer greater precision in drug development, a Stanford University team reports in Nature Communications. Using advanced microscopy techniques, the [...]

Nature’s Painkiller: Natural Molecules Found in Cannabis Rival Morphine in Groundbreaking Study

Researchers at the Comprehensive Center for Pain & Addiction conducted tests on five terpenes, finding promising results in their pain-relief capabilities. A study from the University of Arizona Health Sciences, [...]

The Ultimate Killer: Pollution Deadlier Than War, Terrorism, and Major Diseases

Manmade pollutants and climate change contribute to millions of deaths from cardiovascular disease each year, warn a coalition of leading scientists. A new series published today (June 3) in the Journal of [...]

Scientists Race To Perfect New Oral COVID-19 Treatment Poised To Replace Paxlovid

Rutgers researchers are advancing a potential new COVID-19 treatment, Jun12682, which is effective in animal studies and compatible with other medications, unlike the current leading treatment, Paxlovid. Researchers at Rutgers believe [...]

Penn Medicine Develops Potent mRNA Vaccine Against Lethal H5N1 Virus

Experimental mRNA vaccine proves highly effective against H5N1 in animal studies, offering hope for rapid pandemic response. Researchers from the Perelman School of Medicine at the University of Pennsylvania [...]

The Future of Contraception: Non-Hormonal Birth Control Pill for Men

Baylor researchers developed a reversible, non-hormonal male contraceptive targeting the sperm-specific protein STK33, showing effectiveness and safety in mice studies. In the past six decades, the global population has [...]

Trailblazers in Genetics: Researchers Chase the Cure for Rare Hereditary Diseases

The dynamic structure of FLVCR proteins and their role in nutrient transport within our cells have been revealed. It is known that malfunctions of the proteins FLVCR1 and FLVCR2 [...]

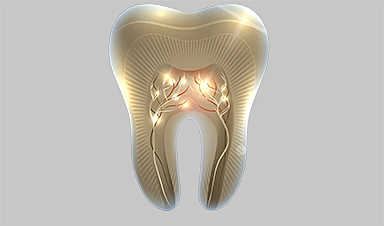

World-first tooth-regrowing drug will be given to humans in September

The world's first human trial of a drug that can regenerate teeth will begin in a few months, less than a year on from news of its success in [...]

New Research Links Tattoos to Increased Risk of Cancer

A new study from Lund University in Sweden suggests that tattoos could be a risk factor for cancer in the lymphatic system, or lymphoma. Now, the researchers underline the [...]

Ultrasound waves are being used to treat everything from hand tremors to addiction

One in four people has a mental disorder, according to the World Health Organization. If you're lucky enough to live in a wealthy country, treatment will usually involve some form [...]

Unseen details of human brain structure revealed

Fully understanding how the human brain works requires knowing the relationships between the various cells that make up the brain. This entails visualizing the brain’s structure on the scale [...]

Microplastics in the ocean might be going undetected

New research suggests that microplastics in our oceans might be hundreds of thousands of times more abundant than current detection methods are reporting. Microplastic particles (MPs) are tiny fragments of [...]

New Study Reveals Shocking Gaps in AI Empathy

Conversational agents (CAs) like Amazon’s Alexa and Apple’s Siri are designed to answer questions, offer suggestions, and even display empathy. However, new research indicates that they fall short compared [...]

Unlocking Memory: Neuroscientists Reveal How the Brain Decides What To Remember

Recent research identifies “sharp wave-ripples” in the hippocampus as a brain mechanism that determines which daily experiences become permanent memories, with significant ripples during idle moments leading to memory [...]

Evolving With the Virus: Repeat COVID-19 Shots Neutralizing Beyond the Expected

The response to an updated vaccine is influenced by previous vaccinations but also produces broadly neutralizing antibodies. The COVID-19 pandemic has ended, yet the virus responsible continues to circulate, hospitalizing thousands weekly and [...]

Study reveals promising development in cancer-fighting nanotechnologies

A new study conducted by the Wilhelm Lab at the University of Oklahoma examines a promising development in biomedical nanoengineering. Published in Advanced Materials, the study explores new findings on the transportation [...]

This modified stainless steel could kill bacteria without antibiotics or chemicals

An electrochemical process developed at Georgia Tech could offer new protection against bacterial infections without contributing to growing antibiotic resistance. The approach capitalizes on the natural antibacterial properties of [...]

Mask Myth Busted? New Research Reveals That Wearing Face Masks Did Not Reduce Risk of COVID Infection

A new study indicates that face masks did not significantly lower Covid-19 infection risk after the initial Omicron wave, highlighting the need for adaptable strategies and further research as [...]

Unlocking Cancer’s Code: Johns Hopkins Researchers Reveal How Cells Go Rogue

Scientists at Johns Hopkins Medicine have mapped a molecular pathway in human breast and lung cells that could lead to excessive genome duplication, a hallmark of cancer cells. The findings, recently [...]

Scientists Uncover Unexpected Hidden Dangers of a Common Antibiotic

In emergency rooms and intensive care units nationwide, healthcare professionals must quickly decide on antibiotics for patients suspected of having severe infections. A recent study from the University of Michigan indicates [...]

New research to make digital transactions quantum safe and 20 times faster

A team of experts, including Monash University researchers, has developed a new technique to implement quantum-safe digital signatures twenty times faster, resulting in speedier and safer online transactions than [...]

Scientists use generative AI to answer complex questions in physics

When water freezes, it transitions from a liquid phase to a solid phase, resulting in a drastic change in properties like density and volume. Phase transitions in water are [...]

An easy pill to swallow—new 3D printing research paves way for personalized medication

A new technique for 3D printing medication has enabled the printing of multiple drugs in a single tablet, paving the way for personalized pills that can deliver timed doses. [...]

Revolutionary “Quartet Nanocage” Vaccine Effective Against Coronaviruses That Haven’t Even Emerged Yet

Researchers have created a new vaccine technology that, in tests with mice, has demonstrated protection against a wide variety of coronaviruses, including those that could cause future disease outbreaks—even [...]

Researchers Warn: AI Systems Have Already Learned How To Deceive Humans

Numerous artificial intelligence (AI) systems, even those designed to be helpful and truthful, have already learned how to deceive humans. In a review article recently published in the journal Patterns, [...]

MIT’s New MRI Technique Reveals Hidden Light Deep in the Brain

A novel MRI technique developed at MIT allows for detailed imaging of bioluminescence deep within the brain, offering new insights into how brain cells develop and communicate with each other. Scientists [...]

Revolutionary mRNA Cancer Vaccine Shows Immense Promise in First-Ever Human Clinical Trial

In a first-ever human clinical trial of four adult patients, an mRNA cancer vaccine created at the University of Florida rapidly reprogrammed the immune system to target glioblastoma, the deadliest and [...]

Human brain map contains never-before-seen details of structure

A cubic millimeter of brain tissue may not sound like much. But considering that tiny square contains 57,000 cells, 230 millimeters of blood vessels, and 150 million synapses, all [...]

AI Ethics Surpass Human Judgment in New Moral Turing Test

AI’s ability to address moral questions is improving, which prompts further considerations for the future. A recent study revealed that when individuals are given two solutions to a moral [...]

AstraZeneca removes its Covid vaccine worldwide after rare side effect

AstraZeneca withdraws COVID-19 vaccine: The pharmaceutical giant AstraZeneca's COVID-19 vaccine is being withdrawn worldwide after the company acknowledged for the first time in court documents that it can cause [...]

AI Transforms Drug Discovery With Faster, Safer Cancer Treatments

The new platform helped UC San Diego scientists synthesize 32 potential multi-target cancer drugs. Scientists at UC San Diego have developed a machine learning algorithm to simulate the time-consuming chemistry involved [...]

Nanotech opens door to future of insulin medication

An international team, led by researchers from Australia, have developed a system using nanotechnology that could allow people with diabetes to take oral insulin in the future. The researchers [...]

COVID-19’s Impact on Child Development More Subtle Than Expected

Researchers at Johns Hopkins Children’s Center express that the study results offer a sense of reassurance, instilling “guarded optimism” regarding the developmental outcomes of young children who have been [...]

New Hope for Neurological Disorders: Scientists Have Discovered How an Essential Nutrient Enters the Brain

Researchers have discovered the process by which dietary choline crosses the blood-brain barrier. This breakthrough has potential applications in enhancing drug delivery to the brain for treating neurological disorders. [...]

Developing a tech platform for fast, robust series production of nanoparticles

Nucleic acid-based medications such as mRNA vaccines offer tremendous potential for medicine and are opening up new therapeutic approaches. These active ingredients must be enclosed inside nanoparticles to ensure [...]

Unlocking Medical Mysteries: Tyche AI’s Revolutionary Insight Into Ambiguity

By providing plausible label maps for one medical image, the Tyche machine-learning model could help clinicians and researchers capture crucial information. In biomedicine, segmentation involves annotating pixels from an [...]

Scientists Decode the Molecular Impact of Exercise

MoTrPAC examined the molecular effects of exercise on 2,600 volunteers, incorporating factors like age, race, and gender diversity. Building upon research in rats, MoTrPAC discovered over 35,000 biological molecules [...]

Prostate Cancer Breakthrough: Urine Test Avoids Unnecessary Biopsies

A study in JAMA Oncology reveals that MyProstateScore 2.0, a new urine test analyzing 18 genes, surpasses PSA in detecting significant prostate cancers and could reduce unnecessary biopsies by up to [...]

Wake Up and Die: New Brain Cell Discovery Could Unlock Alzheimer’s Secrets

This uncommon process is more frequently observed in neurodegenerative diseases and could offer insights into disease mechanisms. According to a new study published in PLOS Biology by Kim Hai-Man Chow and [...]

Challenging Old Theories: Innovative Microscopy Exposes New Alzheimer’s Treatment Pathways

Researchers at UC San Diego have utilized advanced imaging techniques to explore the metabolic processes behind Alzheimer’s disease, leading to potential new strategies for treatment. Alzheimer’s disease, the most common [...]

Cambridge Scientists Discover Simple “Twist” That Supercharges Clean Fuel Generation

Scientists have discovered a method to super-charge the ‘engine’ of sustainable fuel generation – by giving the materials a little twist. The researchers, led by the University of Cambridge, are [...]

Completely New Use Discovered – This Traditional Herb Has Remarkable Nerve Regenerative Properties

Blessed thistle (Cnicus benedictus), a member of the Asteraceae family, thrives in our climate. This plant has been utilized for centuries as a medicinal herb, often consumed as an [...]

Scientists study lipids cell by cell, making new cancer research possible

Imagine being able to look inside a single cancer cell and see how it communicates with its neighbors. Scientists are celebrating a new technique that lets them study the [...]

Antibiotic Breakthrough: Revolutionary Chinese Study Paves Way for Superbug Defeating Drugs

New research reveals that fluorous lipopetides act as highly effective antibiotics. Bacterial infections resistant to multiple drugs, which no existing antibiotics can treat, represent a significant worldwide challenge. A [...]

Signs of Multiple Sclerosis Show Up in Blood Years Before Symptoms Appear

UCSF scientists clear a potential path toward earlier treatment for a disease that affects nearly 1,000,000 people in the United States. By Levi Gadye In a discovery that could hasten [...]

Advanced RNA Sequencing Reveals the Drivers of New COVID Variants

A study reveals that a new sequencing technique, tARC-seq, can accurately track mutations in SARS-CoV-2, providing insights into the rapid evolution and variant development of the virus. The SARS-CoV-2 virus that [...]

No More Endless Boosters? Scientists Develop One-for-All Virus Vaccine

End of the line for endless boosters? Researchers at UC Riverside have developed a new vaccine approach using RNA that is effective against any strain of a virus and can be used safely even by [...]

How Are Hydrogels Shaping the Future of Biomedicine?

Hydrogels have gained widespread recognition and utilization in biomedical engineering, with their applications dating back to the 1960s when they were first used in contact lens production. Hydrogels are [...]

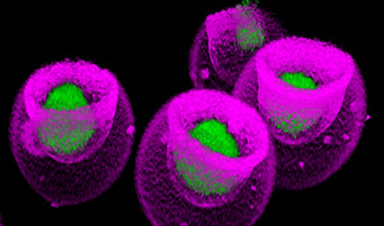

Nanovials method for immune cell screening uncovers receptors that target prostate cancer

A recent UCLA study demonstrates a new process for screening T cells, part of the body's natural defenses, for characteristics vital to the success of cell-based treatments. The method [...]

New Research Reveals That Your Sense of Smell May Be Smarter Than You Think

A new study published in the Journal of Neuroscience indicates that the sense of smell is significantly influenced by cues from other senses, whereas the senses of sight and hearing are [...]

Deadly bacteria show thirst for human blood: the phenomenon of bacterial vampirism

Some of the world's deadliest bacteria seek out and feed on human blood, a newly-discovered phenomenon researchers are calling "bacterial vampirism." A team led by Washington State University researchers [...]

Organ Architects: The Remarkable Cells Shaping Our Development

Finding your way through the winding streets of certain cities can be a real challenge without a map. To orient ourselves, we rely on a variety of information, including [...]

Novel hydrogel removes microplastics from water

Microplastics pose a great threat to human health. These tiny plastic debris can enter our bodies through the water we drink and increase the risk of illnesses. They are [...]

Researchers Discover New Origin of Deep Brain Waves

Understanding hippocampal activity could improve sleep and cognition therapies. Researchers from the University of California, Irvine’s biomedical engineering department have discovered a new origin for two essential brain waves—slow waves and [...]

The Lifelong Cost of Surviving COVID: Scientists Uncover Long-Term Effects

Many of the individuals released to long-term acute care facilities suffered from conditions that lasted for over a year. Researchers at UC San Francisco studied COVID-19 patients in the United States who survived [...]

Previously Unknown Rogue Immune Key to Chronic Viral Infections Discovered

Scientists discovered a previously unidentified rogue immune cell linked to poor antibody responses in chronic viral infections. Australian researchers have discovered a previously unknown rogue immune cell that can [...]

Nature’s Betrayal: Unmasking Lead Lurking in Herbal Medicine

A case of lead poisoning due to Ayurvedic medicine use demonstrates the importance of patient history in diagnosis and the need for public health collaboration to prevent similar risks. [...]

Frozen in Time: How a DNA Anomaly Misled Scientists for Centuries

An enormous meteor spelled doom for most dinosaurs 65 million years ago. But not all. In the aftermath of the extinction event, birds — technically dinosaurs themselves — flourished. [...]

‘Mini kidneys’ reveal new insights into metabolic defects in polycystic kidney disease

Scientists at Nanyang Technological University, Singapore (NTU Singapore) have successfully grown 'mini kidneys' in the lab and grafted them into live mice, revealing new insights into the metabolic defects [...]

Decoding the Origin of Life: Scientists Solve Early Earth RNA Puzzle

Recent research illustrates how RNA molecules’ chemical characteristics might have played a crucial role in the development of complex life forms. How did complex life manage to evolve on [...]

Improving infectious disease testing with gold nanoparticles

By harnessing the power of composite polymer particles adorned with gold nanoparticles, a group of researchers have delivered a more accurate means of testing for infectious diseases. Details of their [...]

New micromaterial releases nanoparticles that selectively destroy cancer cells

Researchers have developed micromaterials made up only of proteins, capable of delivering over an extended period of time nanoparticles that attack specific cancer cells and destroy them. The micromaterials [...]

Alzheimer’s Breakthrough: Scientists Make Revolutionary Leap

Dementia is a major health issue worldwide in the 21st century, impacting over 50 million people globally. This figure is expected to soar to 152 million by 2050, as [...]

How small RNA molecules regulate viral infections of bacteria

Viruses need hosts. Whether it's measles, the flu or coronavirus, viral pathogens cannot multiply or infect other organisms without the assistance of their hosts' cellular infrastructure. However, humans are [...]

Computer scientists discover gap in the latest security mechanisms used by some chips

Over the past few years, hardware manufacturers have developed technologies that ought to make it possible for companies and governmental organizations to process sensitive data securely using shared cloud [...]

Microplastics Are a Big Problem, a New Film Warns

It’s been more than five decades since Dustin Hoffman’s character in “The Graduate” was offered a kernel of wisdom about the path to prosperity. “Plastics,” he’s told by Mr. McGuire, [...]

The Precarious Asymmetries of Human-AI Relationships

KEY POINTS Human-AI interactions are currently asymmetrical, lacking continuity and depth. AI evolution may lead to more sustained, contextually rich user relationships. Balancing asymmetry and connection requires design advocacy [...]

Vaping’s Hidden Dangers: New Study Links E-Cigarettes to DNA Changes

A new study led by researchers from University College London (UCL) and the University of Innsbruck reveals that individuals who use e-cigarettes, despite having a limited history of smoking, undergo similar changes in DNA within [...]

Leave A Comment