The primary function of personal protection equipment (PPE), including facemasks and gloves, is to filter out nanoparticulate aerosols, which are present in the air.

PPE is widely used in medical research, law enforcement, healthcare, and military applications. Conventional PPEs can only filter nanoparticles whose size is above 300 nm and fails to block harmful nanoparticulate aerosols (e.g., virus), which are around 20-300 nm in size.

Recently, scientists developed a lightweight and ultra-compact atomically thin graphene-based filter that can block aerosolized nanoparticles of size in the sub-20 nm range. This study is available in ACS Applied Materials and Interfaces.

Conventional System of Filtering Airborne Nanoparticles

Nanoparticulate aerosols contain toxins, pollutants, and harmful viruses, e.g., influenza virus, coronavirus, and rhinovirus, whose size varies between 20 and 300 nm in diameter. Although conventional air filters, such as 95% efficiency filter (N95) and the high-efficiency particulate air filter (HEPA), exhibit superior air flow rates, they are unable to inhibit nanoparticulate aerosols whose size is less than 300 nm.

Facemasks that can block nanoparticulate aerosols of size below 300 nm are bulky and develop thermal stress due to low breathability. To improve the applicability of PPEs, several strategies are implemented that focus on making porous polymers, with greater thickness, which can filter out nanoparticulate aerosol toxins, pathogens, and pollutants. Two of the major disadvantages of this approach are the inability to provide long-term protection due to inevitable leakages and low breathability owing to the high thickness.

The breathability of conventional polymeric materials has been improved via the introduction of porosity and the development of reactive organic or inorganic composite materials that can inactivate pathogens and degrade harmful substances. Some of the other techniques implemented to improve breathability are the introduction of non-woven materials and the development of hollow fiber membranes via spinning polymer methods.

Nanomaterial Based Filters with Improved Breathability and Filtering Capacity

Fabrication of membranes using nanomaterials, such as vertically aligned carbon nanotubes (CNTs), has led to improved breathability and blockage of nanoparticulate aerosols with a diameter of less than 3 nm. Nevertheless, scientists face challenges in tuning CNT diameters to target specific aerosolized nanoparticulates.

Graphene is an allotrope of carbon with atomic thinness, chemical robustness, superior mechanical strength, and high nanopore density. This material aids in size-selective separation owing to greater tunability. Recently, scientists demonstrated a new strategy to fabricate atomically thin, nanoporous graphene membranes for filtering airborne nanoparticulate of size between 5 and 20 nm with greater airflow i.e., around 7.12 × 10−5 mol m−2 s −1 Pa−1.

The newly synthesized monolayer graphene on copper (Cu) foil, via the chemical vapor deposition (CVD) method, was transferred onto polycarbonate track-etch (PCTE) membrane support containing pores of approximately 200 nm in size. Scanning electron microscopy (SEM) images revealed that synthesized graphene on Cu foil was wrinkled, indicating a continuous graphene layer. Raman spectroscopy with characteristic graphene peak confirms the synthesis of high-quality monolayer graphene film. Analysis of graphene placed on PCTE support via SEM showed that most PCTE pores contained graphene.

Large tears that appeared were mended through the interfacial polymerization (IP) technique. The PCTE support with well-defined cylindrical geometry could seal tears in the graphene layer. It also sealed other macroscopic defects. Post IP, nanopores were introduced through the facile plasma etch of the graphene lattice. These nanopores were characterized to estimate the diffusion-driven flow of ions and molecules, whose sizes ranged between 0.66 nm and 4 nm.

Finally, graphene membranes were mounted in the specially designed setup to determine their performance in filtering aerosol nanoparticles using the silicon dioxide (SiO2) nanoparticle model. The mechanical stability of the membrane was provided by a perforated steel plate. The current study strongly emphasized that a higher air permeability can be offered through an increment in the support pore diameter and support porosity, along with a decrease in the support thickness.

Experimental findings revealed that single-layer graphene on PCTE supports could withstand a pressure difference of up to 100 bars. Nanopore introduced via facile oxygen plasma etch facilitated an increase in the rate of change of pressure values to 3.50 mTorr/s (60 seconds of etch time) and 8.78 mTorr/s (90 seconds of etch times). Further increase in the oxygen plasma time elevated the rate of pressure change until it reached 13.11 mTorr/s in 180 seconds of etch time.

Utilization of SiO2 Nanoparticles Model to Determine the Efficacy of Graphene Filter

Silica aerosols were selected because they are solid spheres with a narrow size distribution. A low concentration of SiO2 nanoparticles was used to exclude the formation of a coating on the graphene filter. Importantly, the rate of change of pressure remained unchanged before and after testing with 5 nm SiO2 nanoparticles.

The graphene filter subjected to 60 seconds of etching showed a distinct change in the rate of pressure, which could be due to the formation of blockage by the nanoparticles. This finding suggested the filtering of aerosolized nanoparticles whose sizes were around 5 nm.

The newly developed compact, lightweight, atomically thin graphene filter can block smaller nanoparticles more effectively and can be applied in medical research, space, healthcare, and beyond.

News

New Once-a-Week Shot Promises Life-Changing Relief for Parkinson’s Patients

A once-a-week shot from Australian scientists could spare people with Parkinson’s the grind of taking pills several times a day. The tiny, biodegradable gel sits under the skin and releases steady doses of two [...]

Weekly injectable drug offers hope for Parkinson’s patients

A new weekly injectable drug could transform the lives of more than eight million people living with Parkinson's disease, potentially replacing the need for multiple daily tablets. Scientists from the University of South Australia [...]

Most Plastic in the Ocean Is Invisible—And Deadly

Nanoplastics—particles smaller than a human hair—can pass through cell walls and enter the food web. New research suggest 27 million metric tons of nanoplastics are spread across just the top layer of the North [...]

Repurposed drugs could calm the immune system’s response to nanomedicine

An international study led by researchers at the University of Colorado Anschutz Medical Campus has identified a promising strategy to enhance the safety of nanomedicines, advanced therapies often used in cancer and vaccine treatments, [...]

Nano-Enhanced Hydrogel Strategies for Cartilage Repair

A recent article in Engineering describes the development of a protein-based nanocomposite hydrogel designed to deliver two therapeutic agents—dexamethasone (Dex) and kartogenin (KGN)—to support cartilage repair. The hydrogel is engineered to modulate immune responses and promote [...]

New Cancer Drug Blocks Tumors Without Debilitating Side Effects

A new drug targets RAS-PI3Kα pathways without harmful side effects. It was developed using high-performance computing and AI. A new cancer drug candidate, developed through a collaboration between Lawrence Livermore National Laboratory (LLNL), BridgeBio Oncology [...]

Scientists Are Pretty Close to Replicating the First Thing That Ever Lived

For 400 million years, a leading hypothesis claims, Earth was an “RNA World,” meaning that life must’ve first replicated from RNA before the arrival of proteins and DNA. Unfortunately, scientists have failed to find [...]

Why ‘Peniaphobia’ Is Exploding Among Young People (And Why We Should Be Concerned)

An insidious illness is taking hold among a growing proportion of young people. Little known to the general public, peniaphobia—the fear of becoming poor—is gaining ground among teens and young adults. Discover the causes [...]

Team finds flawed data in recent study relevant to coronavirus antiviral development

The COVID pandemic illustrated how urgently we need antiviral medications capable of treating coronavirus infections. To aid this effort, researchers quickly homed in on part of SARS-CoV-2's molecular structure known as the NiRAN domain—an [...]

Drug-Coated Neural Implants Reduce Immune Rejection

Summary: A new study shows that coating neural prosthetic implants with the anti-inflammatory drug dexamethasone helps reduce the body’s immune response and scar tissue formation. This strategy enhances the long-term performance and stability of electrodes [...]

Scientists discover cancer-fighting bacteria that ‘soak up’ forever chemicals in the body

A family of healthy bacteria may help 'soak up' toxic forever chemicals in the body, warding off their cancerous effects. Forever chemicals, also known as PFAS (per- and polyfluoroalkyl substances), are toxic chemicals that [...]

Johns Hopkins Researchers Uncover a New Way To Kill Cancer Cells

A new study reveals that blocking ribosomal RNA production rewires cancer cell behavior and could help treat genetically unstable tumors. Researchers at the Johns Hopkins Kimmel Cancer Center and the Department of Radiation Oncology and Molecular [...]

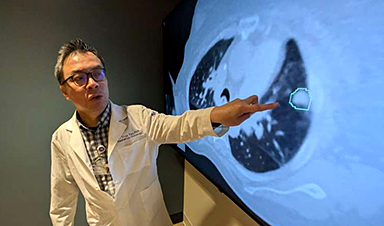

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]