A group of researchers recently published a paper in the MDPI journal pharmaceutics that demonstrated the effectiveness of using lipid-biopolymer nanobeads as indomethacin (INDO) carriers to reduce drug toxicity.

Background

INDO, an orally administered non-steroidal anti-inflammatory (NSAID) agent, is used extensively for inflammation, fever, and pain control. However, the oral administration of INDO often leads to severe side effects, specifically in the gastrointestinal system, such as abdominal ache, indigestion, and diarrhea owing to the first-pass metabolism. Thus, new approaches are being investigated to lessen the INDO systemic toxicity and improve its overall efficacy.

Figure 1. Long-term stability of NLC formulations, monitored in terms of size (A), PDI (B), Zeta potential (C) and pH (D) values for up to a year, at 25 °C (n = 3; p < 0.05). © Bonetti, F.M.R., de Paula, E., Fonseca, B.B. et al. (2022)

Colloidal drug delivery systems (DDS) with improved therapeutic actions can reduce the side effects by releasing the loaded drugs in a sustained manner. For instance, nanostructured lipid carriers (NLC) can be used to load and deliver various anti-inflammatory compounds through several drug administration routes. However, NLC as a colloid cannot provide the mucoadhesion and gastro-resistance required for oral administration of INDO.

Lipid–polymer nanohybrid formulations that contain at least a single nanostructured material in their composition can potentially merge the benefits of every excipient/carrier within a single DDS. Biopolymers are widely utilized as DDS as they are biodegradable, biocompatible, and versatile in nature. For instance, chitosan, a cationic polysaccharide, possesses exceptional mucoadhesive properties, which can be suitable for INDO administration.

However, chitosan displays sensitivity to acid media such as the gastric microenvironment. This issue can be resolved using xanthan gum (XAN), an anionic exopolysaccharide, as the coating agent of the lipid-polymer nanohybrid formulations such as nanobeads.

The Study

In this study, researchers combined two distinct strategies of coating and hybridization to decrease the INDO systemic toxicity and extend its release profile by simulating an oral administration. Initially, lipid–biopolymer nanobeads were synthesized in which NLC blended with chitosan solution encapsulated the INDO, and the nanobeads were coated by XAN. Later, they investigated the efficacy of the synthesized nanobeads and the reduction in INDO toxicity due to them.

Figure 2. Digital photo (left) of hybrid nanobeads (XAN@CHT/NLC-INDO) and particle size distribution (right), estimated by ImageJ software, (n = 3). © Bonetti, F.M.R., de Paula, E., Fonseca, B.B. et al. (2022)

3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT), chitosan, XAN, INDO, Pluronic® 68 (P68), poloxamer, myristyl myristate (MM), coconut oil (CO), and deionized (DI) water with 18 MΩ resistivity were used as the starting materials.

2%, w/v NLC/INDO and NLC as control formulation were synthesized by the ultrasonication emulsification method, where MM acted as a solid lipid, poloxamer as a surfactant, and CO as a liquid lipid. Under magnetic stirring, the lipid phase containing CO and MM was briefly heated without or with 2% INDO at 10oC above the solid lipid melting point.

The aqueous phase containing 2-5% P68 was also heated at a similar temperature and then added to the lipid phase under high-speed homogenization for 3 min at 10,000 rpm in an Ultra-Turrax blender. Eventually, the obtained microemulsion was tip-sonicated at 20 kHz and 500 W in 30 s (on/off) cycles for 20 min, and then cooled in an ice bath to 25oC.

The polydispersity index (PDI) and particle size of the synthesized NLC/INDO and NLC formulations were determined using the dynamic light scattering (DLS) method, while the Zetasizer Nano ZS90 equipment was employed to measure their zeta potential values by electrophoretic light scattering. Researchers also determined the long-term physicochemical stability and in vitro cell viability of the samples and the INDO encapsulation efficiency.

Chitosan was scattered in 50 mL of 0.1% acetic acid, and XAN was dissolved in 50 mL DI water under magnetic stirring. Subsequently, 2% hydroalcoholic INDO solution was mixed with the chitosan solution and stirred at room temperature for 2 h to obtain chitosan/INDO beads.

In the preparation of chitosan/NLC-INDO hybrid nanobeads, half of the acetic acid solution was replaced with NLC loaded with 2% INDO for chitosan solubilization. The final XAN-coated forms were synthesized by initially immersing the aliquots of chitosan/NLC-INDO nanobeads and chitosan/INDO beads into 0.5% w/v XAN aqueous solution, then filtering and cooling them to −20oC, and finally freeze-drying.

Researchers performed the water uptake test and the INDO release test in in vitro mode, and in vivo toxicity assays through the chicken embryo model on the samples.

Observations

Ten distinct NLC formulations without and with INDO were successfully synthesized that showed a pale white color and a homogenous aspect. The physicochemical properties of NLC formulations remained suitable for use even after one year of storage, which indicated their long-term stability, and their INDO encapsulation efficiency was 99%.

The hybrid nanobeads of XAN-coated chitosan and NLC/INDO displayed exceptional thermodynamic, structural, and in vitro swelling properties, which indicated excellent compatibility between the biomaterials, and an extended drug release profile up to 26 hours.

Figure 3. Indomethacin in vitro release from beads (CHT/INDO and XAN@CHT/INDO) and nanobeads (CHT/NLC-INDO and XAN@CHT/NLC-INDO), quantified by UV-vis (λ = 210 nm) at 37 °C, n = 5. © Bonetti, F.M.R., de Paula, E., Fonseca, B.B. et al. (2022)

The synergism observed between the biopolymer and nanolipid excipients helped in preventing the burst release effect within the first two hours of experiments, which simulated a gastric medium, followed by an extended-release in the pH 6.8, simulating an intestinal medium.

The XAN coating on nanobeads acted as a gastro-resistant excipient that protected chitosan and NLC/INDO from an unexpected swelling and prevented drug release in the initial hours of experiments.

The safety of the nanobeads was confirmed in the in vivo toxicity assay in chicken embryos (CE) as the combined benefits of coating and hybridization procedures reduced the inherent toxicity of INDO in chicken embryos.

Taken together, the findings of this study demonstrated that the lipid–biopolymer nanobead can be effectively used for delivering INDO, and other anti-inflammatories, through oral administration.

News

Repurposed drugs could calm the immune system’s response to nanomedicine

An international study led by researchers at the University of Colorado Anschutz Medical Campus has identified a promising strategy to enhance the safety of nanomedicines, advanced therapies often used in cancer and vaccine treatments, [...]

Nano-Enhanced Hydrogel Strategies for Cartilage Repair

A recent article in Engineering describes the development of a protein-based nanocomposite hydrogel designed to deliver two therapeutic agents—dexamethasone (Dex) and kartogenin (KGN)—to support cartilage repair. The hydrogel is engineered to modulate immune responses and promote [...]

New Cancer Drug Blocks Tumors Without Debilitating Side Effects

A new drug targets RAS-PI3Kα pathways without harmful side effects. It was developed using high-performance computing and AI. A new cancer drug candidate, developed through a collaboration between Lawrence Livermore National Laboratory (LLNL), BridgeBio Oncology [...]

Scientists Are Pretty Close to Replicating the First Thing That Ever Lived

For 400 million years, a leading hypothesis claims, Earth was an “RNA World,” meaning that life must’ve first replicated from RNA before the arrival of proteins and DNA. Unfortunately, scientists have failed to find [...]

Why ‘Peniaphobia’ Is Exploding Among Young People (And Why We Should Be Concerned)

An insidious illness is taking hold among a growing proportion of young people. Little known to the general public, peniaphobia—the fear of becoming poor—is gaining ground among teens and young adults. Discover the causes [...]

Team finds flawed data in recent study relevant to coronavirus antiviral development

The COVID pandemic illustrated how urgently we need antiviral medications capable of treating coronavirus infections. To aid this effort, researchers quickly homed in on part of SARS-CoV-2's molecular structure known as the NiRAN domain—an [...]

Drug-Coated Neural Implants Reduce Immune Rejection

Summary: A new study shows that coating neural prosthetic implants with the anti-inflammatory drug dexamethasone helps reduce the body’s immune response and scar tissue formation. This strategy enhances the long-term performance and stability of electrodes [...]

Scientists discover cancer-fighting bacteria that ‘soak up’ forever chemicals in the body

A family of healthy bacteria may help 'soak up' toxic forever chemicals in the body, warding off their cancerous effects. Forever chemicals, also known as PFAS (per- and polyfluoroalkyl substances), are toxic chemicals that [...]

Johns Hopkins Researchers Uncover a New Way To Kill Cancer Cells

A new study reveals that blocking ribosomal RNA production rewires cancer cell behavior and could help treat genetically unstable tumors. Researchers at the Johns Hopkins Kimmel Cancer Center and the Department of Radiation Oncology and Molecular [...]

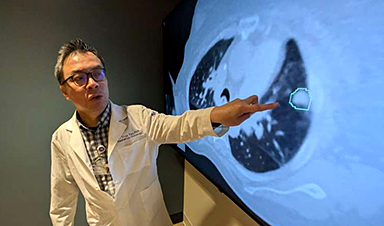

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]

Aging Spreads Through the Bloodstream

Summary: New research reveals that aging isn’t just a local cellular process—it can spread throughout the body via the bloodstream. A redox-sensitive protein called ReHMGB1, secreted by senescent cells, was found to trigger aging features [...]

AI and nanomedicine find rare biomarkers for prostrate cancer and atherosclerosis

Imagine a stadium packed with 75,000 fans, all wearing green and white jerseys—except one person in a solid green shirt. Finding that person would be tough. That's how hard it is for scientists to [...]

Are Pesticides Breeding the Next Pandemic? Experts Warn of Fungal Superbugs

Fungicides used in agriculture have been linked to an increase in resistance to antifungal drugs in both humans and animals. Fungal infections are on the rise, and two UC Davis infectious disease experts, Dr. George Thompson [...]