Nanoemulsions are a relatively new technology that has found significant use for delivering functional chemicals such as micronutrients, flavorings, bioactive molecules, and antimicrobial agents into food and beverage products. This article focuses on applying nanoemulsions for sustainable food processing and packaging in the food sector.

What is a Nanoemulsion?

Nanoemulsions (NEs) are non-equilibrium dispersions of at least two immiscible liquids (oil and water) with droplet sizes of 10–100 nm that are kinetically stable. These nanoemulsions have revolutionized the pharmaceutical, healthcare, skincare and food businesses. They have several remarkable properties, including small droplet size, transparency, enhanced surface area, and reduced sensitivity to chemical and physical changes, making them ideal for food formulations.

Components for the Formation of Nanoemulsions

Core-shell architecture may be used to describe nanoemulsions, and it is made up of three phases: an oil phase (lipophilic), an aqueous phase (amphiphilic), and a surfactant (emulsifier/stabilizer) in precise proportions.

The features of the phases and surfactants should be considered when making nanoemulsions. Surfactants must be carefully selected to achieve an ultra-low interfacial tension (<10-3 mN/m) at the oil/water interface, essential for producing nanoemulsions. The physical and chemical parameters of the oil phase influence the development and stability of nanoemulsions.

Approaches for the Preparation of Nanoemulsions

The size of nanoemulsions is determined by the ingredients, operating circumstances, and technique of manufacture. High-energy or low-energy procedures can be used to make nanoemulsions.

Ultrasonication, microfluidization, and high-pressure homogenization are examples of high-energy procedures that use mechanical devices to disturb the oil phase, allowing it to interact with the water phase and create tiny oil droplets.

To make oil-in-water nanoemulsions, most food industries employ high-energy technologies. Nanoemulsions are made by changing the composition or temperature of the oil-water system in low-energy approaches, including phase inversion composition and phase inversion temperature.

Applications of Nanoemulsions in Food Industry

Most bioactive food components are prone to oxidative deterioration and degradation during food processing. Some bioactive have a low solubility yet a fast metabolism, lowering their bioavailability, whereas others are volatile and sensitive to processing conditions. Utilizing nanoemulsions to encapsulate bioactive chemicals in the food matrix can solve these obstacles.

Encapsulating a bioactive chemical protects it from processing conditions and prevents it from degrading for an extended period due to light, pH, temperature, and oxidative conditions encountered during storage.

Nanoemulsions are an effective method for increasing the digestibility of food and controlling the rate of release and absorption of bioactive chemicals in the gastrointestinal system.

Also, the bioavailability of active ingredients, the pharmacological activity of certain chemicals, and the solubility of pharmaceuticals are all improved by nanoemulsions.

Nanoemulsions can encapsulate useful chemicals and active substances, such as nutraceuticals and antioxidants. Additionally, they are beneficial for the controlled release of flavor components in foods.

Nanoemulsion based Food Packaging

Nanoemulsions can be integrated into coatings and films for possible food packaging applications. Foods such as dairy products, meats, fruit and vegetables can be coated with nanoemulsion-based edible nanocoatings containing flavor and coloring components, enzymes, antioxidants, and antimicrobials agents to extend their shelf life. Coatings can also limit gas exchange, moisture and food oxidation.

Commercialization of Nanoemulsion in Food Products

Nanoemulsions have been employed in food by companies like Nestle and Unilever, as well as a few start-ups. For example, Nestle’s design aids quick and uniform thawing of frozen foods in the microwave, while Unilever utilizes nanoemulsions in ice creams to reduce fat levels from 16 to 1%.

NanoceuticalsTM Slim Shake Chocolate was developed by RBC Life sciences. It utilizes the NanoClusterTM delivery method, which encapsulates dietary supplements in a nanoscale powder. LivOn Labs has created Lypo-SphericTM Vitamin C, which encapsulates Vitamin C using smart liposomal Nanospheres®.

Future Perspectives and Challenges

Nanoemulsions containing bioactive chemicals and functional food components have significant potential in the food and beverage industries. However, food grade nanoemulsions will find broad application only if their manufacturing costs are commercially viable and they fulfill the food industry’s safety regulations.

As a result, enhancing the bioactivity of the encapsulated components is essential for increasing production capacity. Additional research should be conducted to determine the biological events and the risks associated with nanoemulsion-based delivery technologies in food goods and packaging, with the goal of guaranteeing consumer safety.

News

Repurposed drugs could calm the immune system’s response to nanomedicine

An international study led by researchers at the University of Colorado Anschutz Medical Campus has identified a promising strategy to enhance the safety of nanomedicines, advanced therapies often used in cancer and vaccine treatments, [...]

Nano-Enhanced Hydrogel Strategies for Cartilage Repair

A recent article in Engineering describes the development of a protein-based nanocomposite hydrogel designed to deliver two therapeutic agents—dexamethasone (Dex) and kartogenin (KGN)—to support cartilage repair. The hydrogel is engineered to modulate immune responses and promote [...]

New Cancer Drug Blocks Tumors Without Debilitating Side Effects

A new drug targets RAS-PI3Kα pathways without harmful side effects. It was developed using high-performance computing and AI. A new cancer drug candidate, developed through a collaboration between Lawrence Livermore National Laboratory (LLNL), BridgeBio Oncology [...]

Scientists Are Pretty Close to Replicating the First Thing That Ever Lived

For 400 million years, a leading hypothesis claims, Earth was an “RNA World,” meaning that life must’ve first replicated from RNA before the arrival of proteins and DNA. Unfortunately, scientists have failed to find [...]

Why ‘Peniaphobia’ Is Exploding Among Young People (And Why We Should Be Concerned)

An insidious illness is taking hold among a growing proportion of young people. Little known to the general public, peniaphobia—the fear of becoming poor—is gaining ground among teens and young adults. Discover the causes [...]

Team finds flawed data in recent study relevant to coronavirus antiviral development

The COVID pandemic illustrated how urgently we need antiviral medications capable of treating coronavirus infections. To aid this effort, researchers quickly homed in on part of SARS-CoV-2's molecular structure known as the NiRAN domain—an [...]

Drug-Coated Neural Implants Reduce Immune Rejection

Summary: A new study shows that coating neural prosthetic implants with the anti-inflammatory drug dexamethasone helps reduce the body’s immune response and scar tissue formation. This strategy enhances the long-term performance and stability of electrodes [...]

Scientists discover cancer-fighting bacteria that ‘soak up’ forever chemicals in the body

A family of healthy bacteria may help 'soak up' toxic forever chemicals in the body, warding off their cancerous effects. Forever chemicals, also known as PFAS (per- and polyfluoroalkyl substances), are toxic chemicals that [...]

Johns Hopkins Researchers Uncover a New Way To Kill Cancer Cells

A new study reveals that blocking ribosomal RNA production rewires cancer cell behavior and could help treat genetically unstable tumors. Researchers at the Johns Hopkins Kimmel Cancer Center and the Department of Radiation Oncology and Molecular [...]

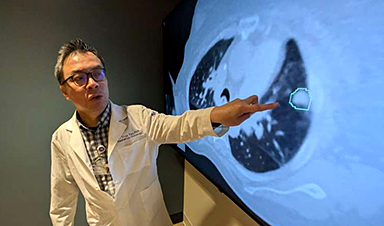

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]

Aging Spreads Through the Bloodstream

Summary: New research reveals that aging isn’t just a local cellular process—it can spread throughout the body via the bloodstream. A redox-sensitive protein called ReHMGB1, secreted by senescent cells, was found to trigger aging features [...]

AI and nanomedicine find rare biomarkers for prostrate cancer and atherosclerosis

Imagine a stadium packed with 75,000 fans, all wearing green and white jerseys—except one person in a solid green shirt. Finding that person would be tough. That's how hard it is for scientists to [...]

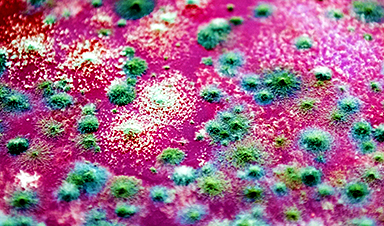

Are Pesticides Breeding the Next Pandemic? Experts Warn of Fungal Superbugs

Fungicides used in agriculture have been linked to an increase in resistance to antifungal drugs in both humans and animals. Fungal infections are on the rise, and two UC Davis infectious disease experts, Dr. George Thompson [...]