| A new 3D printing technology makes the production of complex metallic objects at the nanoscale possible. A team of chemists led by a scientist from the University of Oldenburg has developed an electrochemical technique that can be used to make objects out of copper just 25 nanometres in diameter. | |

| The new technique is based on the well-known process of electroplating, the team reports in the journal Nano Letters (“Bringing Electrochemical Three-Dimensional Printing to the Nanoscale”). |

| In recent years 3D printing, also known as additive manufacturing, has established itself as a promising new manufacturing process for a wide variety of components. Dr Dmitry Momotenko, a chemist at the University of Oldenburg, has now succeeded in fabricating ultrasmall metal objects using a new 3D printing technique. | |

| In a paper published together with a team of researchers from ETH Zurich (Switzerland) and Nanyang Technological University (Singapore) in the scientific journal Nano Letters, he reports that the technique has potential applications in microelectronics, sensor technology and battery technology. | |

| The team has developed an electrochemical technique that can be used to make objects out of copper just 25 billionths of a metre (equivalent to 25 nanometres) in diameter. For comparison, a human hair is about 3000 times thicker than the filigree nanostructures. | |

| The new printing technique is based on the comparatively simple and well-known process of electroplating. In electroplating, positively charged metal ions are suspended in a solution. When the liquid comes into contact with a negatively charged electrode, the metal ions combine with the electrons in the electrode to form neutral metal atoms which are then deposited on the electrode and gradually form a solid metal layer. | |

| “In this process, a solid metal is fabricated from a liquid salt solution – a process that we electrochemists can control very effectively,” says Momotenko. | |

| For his nanoprinting technique he uses a solution of positively charged copper ions in a tiny pipette. The liquid emerges from the tip of the pipette through a print nozzle. In the team’s experiments the nozzle opening had a diameter of between 253 and 1.6 nanometres. Only two copper ions can pass through such a tiny opening simultaneously. | |

| The biggest challenge for the scientists was that as the metal layer grows, the opening of the print nozzle tends to get clogged. To prevent this the team developed a technique for monitoring the progress of the printing process. | |

| They recorded the electrical current between the negatively charged substrate electrode and a positive electrode inside the pipette and then the movement of the nozzle was adjusted accordingly in a fully automated process: the nozzle approached the negative electrode for a very short time and then retracted as soon as the metal layer had exceeded a certain thickness. Using this technique, the researchers gradually applied one copper layer after another to the electrode’s surface. | |

| Thanks to the extremely precise positioning of the nozzle they were able to print both vertical columns and inclined or spiral nanostructures, and even managed to produce horizontal structures by simply changing the printing direction. | |

| They were also able to control the diameter of the structures very precisely – firstly through the choice of print nozzle size and secondly during the actual printing process on the basis of electrochemical parameters. According to the team, the smallest possible objects that can be printed using this method have a diameter of about 25 nanometres, which is equivalent to 195 copper atoms in a row. | |

| That means that with the new electrochemical technique it is possible to print far smaller metal objects than have ever been printed before. 3D printing using metal powders, for example – a typical method for 3D printing of metals – can currently achieve a resolution of about 100 micrometres. | |

| The smallest objects that can be produced using this method are therefore 4,000 times larger than those in the current study. Although even smaller structures can be produced using other techniques, the choice of potential materials is limited. | |

| “The technology we are working on combines both worlds – metal printing and nanoscale precision,” says Momotenko. Just as 3D printing has sparked a revolution in the production of complex larger components, additive manufacturing at the micro- and nanoscales could make it possible to fabricate functional structures and even devices with ultrasmall dimensions, he explains. | |

| “3D-printed catalysts with high surface area and special geometry to allow particular reactivity could be prepared for the production of complex chemicals,” says Momotenko. Three-dimensional electrodes could make electrical energy storage more efficient, he adds. | |

| The chemist and his team are currently working towards this very goal: in their NANO-3D-LION project they aim to drastically increase the surface area of electrodes and reduce distances between the cathode and the anode in lithium-ion batteries through 3D printing, in order to speed up the charging process. |

| Source: Carl von Ossietzky-Universität Oldenburg |

News

Repurposed drugs could calm the immune system’s response to nanomedicine

An international study led by researchers at the University of Colorado Anschutz Medical Campus has identified a promising strategy to enhance the safety of nanomedicines, advanced therapies often used in cancer and vaccine treatments, [...]

Nano-Enhanced Hydrogel Strategies for Cartilage Repair

A recent article in Engineering describes the development of a protein-based nanocomposite hydrogel designed to deliver two therapeutic agents—dexamethasone (Dex) and kartogenin (KGN)—to support cartilage repair. The hydrogel is engineered to modulate immune responses and promote [...]

New Cancer Drug Blocks Tumors Without Debilitating Side Effects

A new drug targets RAS-PI3Kα pathways without harmful side effects. It was developed using high-performance computing and AI. A new cancer drug candidate, developed through a collaboration between Lawrence Livermore National Laboratory (LLNL), BridgeBio Oncology [...]

Scientists Are Pretty Close to Replicating the First Thing That Ever Lived

For 400 million years, a leading hypothesis claims, Earth was an “RNA World,” meaning that life must’ve first replicated from RNA before the arrival of proteins and DNA. Unfortunately, scientists have failed to find [...]

Why ‘Peniaphobia’ Is Exploding Among Young People (And Why We Should Be Concerned)

An insidious illness is taking hold among a growing proportion of young people. Little known to the general public, peniaphobia—the fear of becoming poor—is gaining ground among teens and young adults. Discover the causes [...]

Team finds flawed data in recent study relevant to coronavirus antiviral development

The COVID pandemic illustrated how urgently we need antiviral medications capable of treating coronavirus infections. To aid this effort, researchers quickly homed in on part of SARS-CoV-2's molecular structure known as the NiRAN domain—an [...]

Drug-Coated Neural Implants Reduce Immune Rejection

Summary: A new study shows that coating neural prosthetic implants with the anti-inflammatory drug dexamethasone helps reduce the body’s immune response and scar tissue formation. This strategy enhances the long-term performance and stability of electrodes [...]

Scientists discover cancer-fighting bacteria that ‘soak up’ forever chemicals in the body

A family of healthy bacteria may help 'soak up' toxic forever chemicals in the body, warding off their cancerous effects. Forever chemicals, also known as PFAS (per- and polyfluoroalkyl substances), are toxic chemicals that [...]

Johns Hopkins Researchers Uncover a New Way To Kill Cancer Cells

A new study reveals that blocking ribosomal RNA production rewires cancer cell behavior and could help treat genetically unstable tumors. Researchers at the Johns Hopkins Kimmel Cancer Center and the Department of Radiation Oncology and Molecular [...]

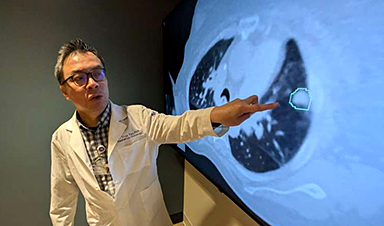

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]

Aging Spreads Through the Bloodstream

Summary: New research reveals that aging isn’t just a local cellular process—it can spread throughout the body via the bloodstream. A redox-sensitive protein called ReHMGB1, secreted by senescent cells, was found to trigger aging features [...]

AI and nanomedicine find rare biomarkers for prostrate cancer and atherosclerosis

Imagine a stadium packed with 75,000 fans, all wearing green and white jerseys—except one person in a solid green shirt. Finding that person would be tough. That's how hard it is for scientists to [...]

Are Pesticides Breeding the Next Pandemic? Experts Warn of Fungal Superbugs

Fungicides used in agriculture have been linked to an increase in resistance to antifungal drugs in both humans and animals. Fungal infections are on the rise, and two UC Davis infectious disease experts, Dr. George Thompson [...]