Antimony-based substances have good prospects as anode materials in sodium-ion batteries (SIBs) because of their great hypothetical capacity. Unfortunately, the high volumetric growth and limited ion conduction in the electrolytic procedure prevent them from meeting their theoretical capabilities.

In a study published in the journal Carbon, H2/C heat reduction, selenization and sulfurization (SAS) of sodium stibogluconate resulted in Sb2Se3@C and Sb2S3@C nanodots with consistent diameters of 20.7 nm and 19 nm, respectively.

Antimony-based Materials for Sodium-Ion Batteries

Many attempts have been made to investigate suitable electrode substances for sodium-ion batteries (SIBs). Because of their increased capacities compared to anode materials based on intercalation, alloying and conversion-based electrode substances have gained popularity.

Antimony-based substances (Sb, SnSb, Sb2Se3, Sb2S3) are possible anode substances for sodium-ion batteries having unique electrolytic mechanisms and significant hypothetical capacities. Owing to their large hypothetical specific capacities, Sb2Se3 and Sb2S3 are particularly appealing options.

Unfortunately, considerable volumetric growth and inadequate ionic conduction in their electrochemical process are the two fundamental issues that cause quick capacity degradation and poor rate performance at high current density.

Sb2Se3 and Sb2S3 are chalcogenides based on antimony with differing anions, resulting in variations in makeup and conduction. Studies of the influence of various anions on the volumetric growth of the electrode morphology, the capacity to attach with sodium ions (Na+) in the charging/discharging phase, and ionic conduction are of particular importance in the development of electrode components for sodium-ion batteries.

Given that both substances have quick capacity degradation and poor rate performance, avoiding failure of the structure and enhancing electrode conductance are considered primary goals.

Addressing the Limitations of Antimony-based Materials

In general, logical structural design and carbon encapsulation are excellent solutions to these critical issues. Using nanoscale materials may reduce ionic diffusion paths and speed up the interchange of electrons and Na+ ions.

During insertion/removal of sodium ions, the composite carbon is advantageous for accelerating electron transport and improving structural integrity. As a result, a range of Sb2Se3@C and Sb2S3@C composites have been investigated for sodium-ion batteries.

Sb2Se3 nanowires, rod-shaped Sb2S3, and Sb2S3@PPy micro-clips have all been documented thus far. While beneficial electrolytic performance has been achieved, the short cyclic life and extensive examination of the relationship between morphology and Na storing efficiency need additional investigation.

A suitable technique for obtaining extended cyclic life has been proposed to be the construction of an interlinked conducting carbon framework outside of the standalone nanodots (NDs).

Analysis Techniques Used in the Study

Power X-ray diffraction (XRD) was used to describe the crystallographic characteristics. The existence of amorphous carbon with sulfur or selenium loading was verified by Raman spectroscopy, and the amount of amorphous carbon was validated by thermogravimetric assessment.

Transmission electron microscopy (TEM) imaging was used to indicate the unique morphological makeup and distribution of particle sizes. The electrolytic capabilities of the two electrodes for sodium-ion batteries were evaluated using galvanostatic charging/discharging experiments. Density functional theory (DFT) computations were performed to further validate on an atomic level the sodium ion storing kinetics.

Important Findings

In this study, the team synthesized Sb2X3 (where X is Se or S) NDs@C from sodium stibogluconate using a complex pyrolytic technique and utilized them as anode components for sodium-ion batteries. Nanodots having particle sizes of around 19-21 nanometers were encased in a conducting carbon framework loaded with selenium or sulfur.

Each Sb2Se3 and Sb2S3 nanodot was covered by a weakly graphitized interlinking carbon matrix, which was then crosslinked to generate a highly conductive framework.

The reversible capacity displayed by the Sb2Se3 NDs@C electrode was about 316 mA h g-1 following 100 cycles at 100 mA g-1 and about 269 mA h g-1 following 200 cycles at 1 A g-1.

The extremely small nanodot architecture, limited shielding of the crosslinked carbon framework, superior electric conductance, and reduced hypothetical volumetric growth throughout the recurring alloying and converting operations all contributed to the improved electrolytic performance.

Density functional theory computations revealed that Sb2Se3 NDs@C has a lower sodium ion diffusion energy threshold, stronger product-carbon bonding, and more vacant energy bands, which should result in more solid sodium ion storing kinetics and rate performance.

Given the ease of manufacturing, good yield, cheap cost, and excellent electrolytic performance, this research may pave the way for developing upscaled multifunction electrodes using Sb-based coordination compounds in zero to three dimensions.

News

Nano-Enhanced Hydrogel Strategies for Cartilage Repair

A recent article in Engineering describes the development of a protein-based nanocomposite hydrogel designed to deliver two therapeutic agents—dexamethasone (Dex) and kartogenin (KGN)—to support cartilage repair. The hydrogel is engineered to modulate immune responses and promote [...]

New Cancer Drug Blocks Tumors Without Debilitating Side Effects

A new drug targets RAS-PI3Kα pathways without harmful side effects. It was developed using high-performance computing and AI. A new cancer drug candidate, developed through a collaboration between Lawrence Livermore National Laboratory (LLNL), BridgeBio Oncology [...]

Scientists Are Pretty Close to Replicating the First Thing That Ever Lived

For 400 million years, a leading hypothesis claims, Earth was an “RNA World,” meaning that life must’ve first replicated from RNA before the arrival of proteins and DNA. Unfortunately, scientists have failed to find [...]

Why ‘Peniaphobia’ Is Exploding Among Young People (And Why We Should Be Concerned)

An insidious illness is taking hold among a growing proportion of young people. Little known to the general public, peniaphobia—the fear of becoming poor—is gaining ground among teens and young adults. Discover the causes [...]

Team finds flawed data in recent study relevant to coronavirus antiviral development

The COVID pandemic illustrated how urgently we need antiviral medications capable of treating coronavirus infections. To aid this effort, researchers quickly homed in on part of SARS-CoV-2's molecular structure known as the NiRAN domain—an [...]

Drug-Coated Neural Implants Reduce Immune Rejection

Summary: A new study shows that coating neural prosthetic implants with the anti-inflammatory drug dexamethasone helps reduce the body’s immune response and scar tissue formation. This strategy enhances the long-term performance and stability of electrodes [...]

Scientists discover cancer-fighting bacteria that ‘soak up’ forever chemicals in the body

A family of healthy bacteria may help 'soak up' toxic forever chemicals in the body, warding off their cancerous effects. Forever chemicals, also known as PFAS (per- and polyfluoroalkyl substances), are toxic chemicals that [...]

Johns Hopkins Researchers Uncover a New Way To Kill Cancer Cells

A new study reveals that blocking ribosomal RNA production rewires cancer cell behavior and could help treat genetically unstable tumors. Researchers at the Johns Hopkins Kimmel Cancer Center and the Department of Radiation Oncology and Molecular [...]

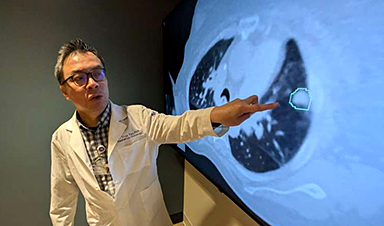

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]

Aging Spreads Through the Bloodstream

Summary: New research reveals that aging isn’t just a local cellular process—it can spread throughout the body via the bloodstream. A redox-sensitive protein called ReHMGB1, secreted by senescent cells, was found to trigger aging features [...]

AI and nanomedicine find rare biomarkers for prostrate cancer and atherosclerosis

Imagine a stadium packed with 75,000 fans, all wearing green and white jerseys—except one person in a solid green shirt. Finding that person would be tough. That's how hard it is for scientists to [...]

Are Pesticides Breeding the Next Pandemic? Experts Warn of Fungal Superbugs

Fungicides used in agriculture have been linked to an increase in resistance to antifungal drugs in both humans and animals. Fungal infections are on the rise, and two UC Davis infectious disease experts, Dr. George Thompson [...]

Scientists Crack the 500-Million-Year-Old Code That Controls Your Immune System

A collaborative team from Penn Medicine and Penn Engineering has uncovered the mathematical principles behind a 500-million-year-old protein network that determines whether foreign materials are recognized as friend or foe. How does your body [...]