Fragile mRNA molecules used in COVID-19 vaccines can’t get into cells on their own. They owe their success to lipid nanoparticles that took decades to refine.

Messenger RNA (mRNA) is having a moment. This year, hundreds of millions of people will receive shots of the Pfizer-BioNTech or Moderna vaccines for COVID-19. The crucial ingredient in each injection is mRNA, short-lived strands of genetic material that prompt our cells to start making SARS-CoV-2 proteins, which in turn help our immune systems develop antibodies that prevent future infections. Thanks to decades of scientific perseverance, billions of dollars of investment in the technology, and previous work on coronaviruses, the vaccine makers were able to design their vaccines and prove their safety and efficacy in under a year.

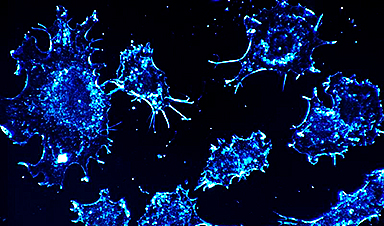

The success of these COVID-19 vaccines is remarkable and was far from guaranteed. mRNA is incredibly delicate. Enzymes in the environment and in our bodies are quick to chop mRNA into pieces, making lab experiments difficult and the delivery of mRNA to our cells daunting. On top of that, mRNA strands are large and negatively charged and can’t simply waltz across the protective lipid membranes of cells. Many scientists thought the technology would never work.

“There were many, many skeptics,” says Frank DeRosa, who began working with mRNA in 2008 and is now chief technology officer at Translate Bio, a firm developing mRNA vaccines with Sanofi. “People used to say that if you looked at it wrong it would fall apart.”

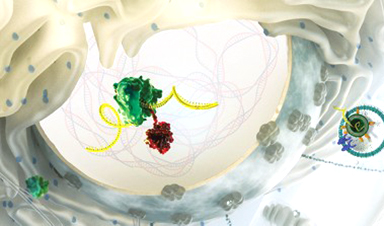

Luckily, scientists found a solution. To protect the fragile molecule as it sneaks into cells, they turned to a delivery technology with origins older than the idea of mRNA therapy itself: tiny balls of fat called lipid nanoparticles, or LNPs.

LNPs used in the COVID-19 vaccines contain just four ingredients: ionizable lipids whose positive charges bind to the negatively charged backbone of mRNA, pegylated lipids that help stabilize the particle, and phospholipids and cholesterol molecules that contribute to the particle’s structure. Thousands of these four components encapsulate mRNA, shield it from destructive enzymes, and shuttle it into cells, where the mRNA is unloaded and used to make proteins. Although the concept seems simple, perfecting it was far from straightforward.

It is a tremendous vindication for everyone working in controlled drug delivery.Robert Langer, chemical engineer, Massachusetts Institute of Technology

Over more than 3 decades, promising lipids studied in the lab often failed to live up to their potential when tested in animals or humans. Positively charged lipids are inherently toxic, and companies struggled for years before landing on formulations that were safe and effective. When injected intravenously, the particles invariably accumulated in the liver, and delivery to other organs is still an obstacle. Reliably manufacturing consistent LNPs was another challenge, and producing the raw materials needed to make the particles is a limiting factor in the production of COVID-19 vaccines today.

LNP development has been a headache, but without this packaging, mRNA vaccines would be nothing. “It is the unsung hero of the whole thing,” says Giuseppe Ciaramella, who was head of infectious diseases at Moderna from 2014 to 2018…..

News

The Silent Battle Within: How Your Organs Choose Between Mom and Dad’s Genes

Research reveals that selective expression of maternal or paternal X chromosomes varies by organ, driven by cellular competition. A new study published today (July 26) in Nature Genetics by the Lymphoid Development Group at the MRC [...]

Study identifies genes increasing risk of severe COVID-19

Whether or not a person becomes seriously ill with COVID-19 depends, among other things, on genetic factors. With this in mind, researchers from the University Hospital Bonn (UKB) and the University of Bonn, in [...]

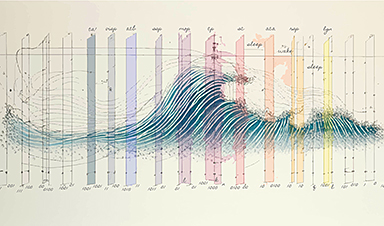

Small regions of the brain can take micro-naps while the rest of the brain is awake and vice versa

Sleep and wake: They're totally distinct states of being that define the boundaries of our daily lives. For years, scientists have measured the difference between these instinctual brain processes by observing brain waves, with [...]

Redefining Consciousness: Small Regions of the Brain Can Take Micro-Naps While the Rest of the Brain Is Awake

The study broadly reveals how fast brain waves, previously overlooked, establish fundamental patterns of sleep and wakefulness. Scientists have developed a new method to analyze sleep and wake states by detecting ultra-fast neuronal activity [...]

AI Reveals Health Secrets Through Facial Temperature Mapping

Researchers have found that different facial temperatures correlate with chronic illnesses like diabetes and high blood pressure, and these can be detected using AI with thermal cameras. They highlight the potential of this technology [...]

Breakthrough in aging research: Blocking IL-11 extends lifespan and improves health in mice

In a recent study published in the journal Nature, a team of researchers used murine models and various pharmacological and genetic approaches to examine whether pro-inflammatory signaling involving interleukin (IL)-11, which activates signaling molecules such [...]

Promise for a universal influenza vaccine: Scientists validate theory using 1918 flu virus

New research led by Oregon Health & Science University reveals a promising approach to developing a universal influenza vaccine—a so-called "one and done" vaccine that confers lifetime immunity against an evolving virus. The study, [...]

New Projects Aim To Pioneer the Future of Neuroscience

One study will investigate the alterations in brain activity at the cellular level caused by psilocybin, the psychoactive substance found in “magic mushrooms.” How do neurons respond to the effects of magic mushrooms? What [...]

Decoding the Decline: Scientific Insights Into Long COVID’s Retreat

Research indicates a significant reduction in long COVID risk, largely due to vaccination and the virus’s evolution. The study analyzes data from over 441,000 veterans, showing lower rates of long COVID among vaccinated individuals compared [...]

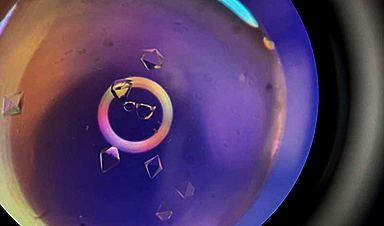

Silicon Transformed: A Breakthrough in Laser Nanofabrication

A new method enables precise nanofabrication inside silicon using spatial light modulation and laser pulses, creating advanced nanostructures for potential use in electronics and photonics. Silicon, the cornerstone of modern electronics, photovoltaics, and photonics, [...]

Caught in the actinium: New research could help design better cancer treatments

The element actinium was first discovered at the turn of the 20th century, but even now, nearly 125 years later, researchers still don't have a good grasp on the metal's chemistry. That's because actinium [...]

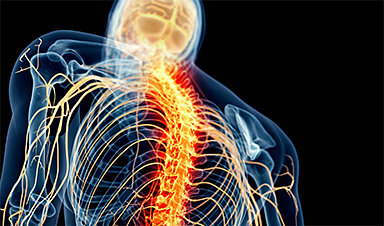

Innovative Light-Controlled Drugs Could Revolutionize Neuropathic Pain Treatment

A team of researchers from the Institute for Bioengineering of Catalonia (IBEC) has developed light-activated derivatives of the anti-epileptic drug carbamazepine to treat neuropathic pain. Light can be harnessed to target drugs to specific [...]

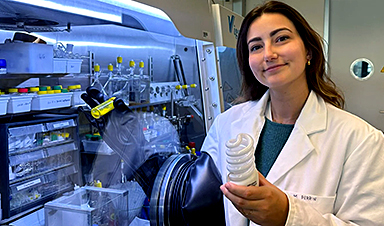

Green Gold: Turning E-Waste Into a Treasure Trove of Rare Earth Metals

Scientists are developing a process inspired by nature that efficiently recovers europium from old fluorescent lamps. The approach could lead to the long-awaited recycling of rare earth metals. A small molecule that naturally serves [...]

Cambridge Study: AI Chatbots Have an “Empathy Gap,” and It Could Be Dangerous

A new study suggests a framework for “Child Safe AI” in response to recent incidents showing that many children perceive chatbots as quasi-human and reliable. A study has indicated that AI chatbots often exhibit [...]

Nanoparticle-based delivery system could offer treatment for diabetics with rare insulin allergy

Up to 3% of people with diabetes have an allergic reaction to insulin. A team at Forschungszentrum Jülich has now studied a method that could be used to deliver the active substance into the [...]

Nanorobot kills cancer cells in mice with hidden weapon

Researchers at Karolinska Institutet in Sweden have developed nanorobots that kill cancer cells in mice. The robot's weapon is hidden in a nanostructure and is exposed only in the tumor microenvironment, sparing healthy cells. [...]