Grinding is an essential manufacturing process, yet the heat due to friction associated with the process causes damage to the part being processed. Lubrication is used to reduce friction; however, traditional petroleum-based lubricants can harm the environment and are hazardous to humans.

A paper published in the Journal of Cleaner Production addresses the issues associated with traditional lubricants and presents a novel eco-friendly technique to develop lubricating fluid using nanoparticles.

Grinding – Its Importance and Implications

Grinding is one of the most popular precision manufacturing methods for producing parts, offering excellent surface integrity and fine dimensional tolerances at a reduced cost. Nevertheless, the synchronized rubbing, shearing, and plowing action of randomly dispersed abrasive grains create a large amount of heat due to friction in the machining area.

It is important to note that almost all of the energy produced during the grinding process is converted to heat energy. The bulk of this heat permeates the machined part, especially difficult-to-machine materials (DTMMs). This high temperature has a significant influence on surface quality and grinding performance.

The Impact of Lubricating Fluids

To counteract the problem of overheating and ensure the highest possible grinding performance, lubrication for grinding purposes has emerged as a current area of primary scientific focus.

For decades, various lubricating fluids have been used to improve the grinding performance by reducing surplus heat within the machining area. Unfortunately, 85% of these machining fluids are petroleum-based lubricating fluids derived from crude oil extracts and extracts containing chemical additives such as chlorine.

The Negative Side of Lubricants

This whole process has extremely negative environmental repercussions, including soil and water contamination, as well as adverse health implications for machine workers, such as cancer, breathing issues, dermatitis, and genetic illnesses.

As a result, it has become important to investigate practical and sustainable manufacturing solutions that are economically viable, safe for the community, waste-free, and limit negative environmental consequences.

A Transition Towards Green Eco-Friendly Lubrication

Vegetable-based oils are considered ideal options for replacing conventional lubricating fluids to make that progress toward green eco-friendly lubrication.

Vegetable-based oils have a relatively high viscosity, are biodegradable, and have great dispersion properties. Furthermore, straight vegetable-based oils provide an extra-strong lubricant layer that interacts aggressively with the metallic surface, reducing wear due to friction.

Many research teams have attempted to employ vegetable-based oils as lubricants for minimal quantity lubrication (MQL)-based grinding of DTMMs to replace traditional lubricating fluids.

Nanofluids – Overcoming Lubrication Barriers

Although various investigations have shown that MQL has superior lubricating properties, the cooling efficacy of MQL-based grinding is not optimum.

To resolve the issue of low cooling efficacy, a new kind of lubricant, nanofluid (NFs), may be manufactured to improve heat transmission.

Many researchers have emphasized the significant advantages of NFs over traditional lubricating fluids in grinding. As a result, NFs are used extensively in grinding-based processes to increase surface quality and reduce machining loads.

Basis of Current Research in Eco-Friendly Lubricants

The current study aimed to investigate the viability of eco-friendly vegetable-based lubricants, such as aluminum oxide-based NFs, in MQL-based grinding of AISI tool steel. The study aimed to consider technology used, sustainability, and product quality factors.

A variety of lubricants were used as the base fluid for MQL-based grinding in the study to determine the impact of the lubricating fluid and to analyze the cooling performance of the fluid on the AISI tool steel’s technological and sustainability indices, including energy consumption, carbon emission, manufacturing costs, friction coefficient, roughness, BC proportion, surface characteristics, and microchip morphology.

Results of the Study

Through thorough research, the team pointed out that a sustainable MQL-based system with eco-friendly nanoparticle-based lubricants, particularly aluminum oxide-based NFs, is the ideal solution for lubricants in the precision machining industries for eco-friendly fabrication of steel components.

The aluminum oxide-based NFs method dramatically improved grinding performance, surface quality, and sustainability.

The team concluded that a wide range of precision machining-based industries has potential usage for sustainable, eco-friendly grinding. Thus, making NFs a very desirable lubricant when it comes to grinding-based processes.

News

Team finds flawed data in recent study relevant to coronavirus antiviral development

The COVID pandemic illustrated how urgently we need antiviral medications capable of treating coronavirus infections. To aid this effort, researchers quickly homed in on part of SARS-CoV-2's molecular structure known as the NiRAN domain—an [...]

Drug-Coated Neural Implants Reduce Immune Rejection

Summary: A new study shows that coating neural prosthetic implants with the anti-inflammatory drug dexamethasone helps reduce the body’s immune response and scar tissue formation. This strategy enhances the long-term performance and stability of electrodes [...]

Scientists discover cancer-fighting bacteria that ‘soak up’ forever chemicals in the body

A family of healthy bacteria may help 'soak up' toxic forever chemicals in the body, warding off their cancerous effects. Forever chemicals, also known as PFAS (per- and polyfluoroalkyl substances), are toxic chemicals that [...]

Johns Hopkins Researchers Uncover a New Way To Kill Cancer Cells

A new study reveals that blocking ribosomal RNA production rewires cancer cell behavior and could help treat genetically unstable tumors. Researchers at the Johns Hopkins Kimmel Cancer Center and the Department of Radiation Oncology and Molecular [...]

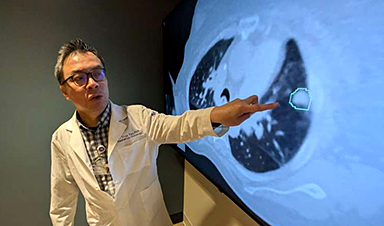

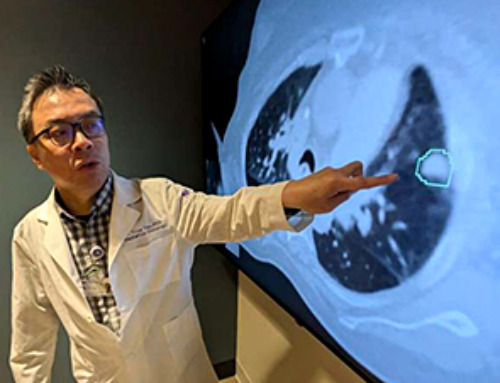

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]

Aging Spreads Through the Bloodstream

Summary: New research reveals that aging isn’t just a local cellular process—it can spread throughout the body via the bloodstream. A redox-sensitive protein called ReHMGB1, secreted by senescent cells, was found to trigger aging features [...]

AI and nanomedicine find rare biomarkers for prostrate cancer and atherosclerosis

Imagine a stadium packed with 75,000 fans, all wearing green and white jerseys—except one person in a solid green shirt. Finding that person would be tough. That's how hard it is for scientists to [...]

Are Pesticides Breeding the Next Pandemic? Experts Warn of Fungal Superbugs

Fungicides used in agriculture have been linked to an increase in resistance to antifungal drugs in both humans and animals. Fungal infections are on the rise, and two UC Davis infectious disease experts, Dr. George Thompson [...]

Scientists Crack the 500-Million-Year-Old Code That Controls Your Immune System

A collaborative team from Penn Medicine and Penn Engineering has uncovered the mathematical principles behind a 500-million-year-old protein network that determines whether foreign materials are recognized as friend or foe. How does your body [...]

Team discovers how tiny parts of cells stay organized, new insights for blocking cancer growth

A team of international researchers led by scientists at City of Hope provides the most thorough account yet of an elusive target for cancer treatment. Published in Science Advances, the study suggests a complex signaling [...]

Nanomaterials in Ophthalmology: A Review

Eye diseases are becoming more common. In 2020, over 250 million people had mild vision problems, and 295 million experienced moderate to severe ocular conditions. In response, researchers are turning to nanotechnology and nanomaterials—tools that are transforming [...]

Natural Plant Extract Removes up to 90% of Microplastics From Water

Researchers found that natural polymers derived from okra and fenugreek are highly effective at removing microplastics from water. The same sticky substances that make okra slimy and give fenugreek its gel-like texture could help [...]

Instant coffee may damage your eyes, genetic study finds

A new genetic study shows that just one extra cup of instant coffee a day could significantly increase your risk of developing dry AMD, shedding fresh light on how our daily beverage choices may [...]