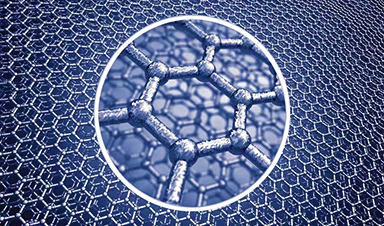

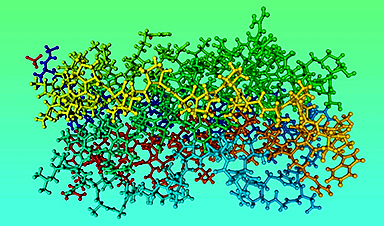

In a study printed in the journal ACS Applied Materials & Interfaces, chemical vapor deposition approach was used to produce a nanometric hexagonal boron nitride (h-BN) coating on the cambered sides of every fiber in graphene glass fiber fabric (GGFF).

Encapsulating Carbon-based Materials can Improve Oxidation Resistance

Owing to their superior thermal and electrical characteristics, carbon-based materials like carbon fiber, graphene, and carbon nanotubes, are commonly employed in electronic systems.

The chemical and thermal stabilities of carbonaceous electronic systems are pivotal prerequisites for their long-term steady operation.

On the other hand, these materials face the difficult problem of oxidation, particularly when operating at high temperatures. Encapsulation is among the most effective methods for increasing the oxidative resistance of materials via oxygen isolation.

Pros and Cons of Different Encapsulating Materials

Thanks to their accessibility, flexibility, and affordability, organic polymers like polyurethane, polypropylene, polyethene, and poly-(vinylidene chloride) are commonly utilized for encapsulating devices. Their low thermal stabilities, however, restrict their usage in settings having temperatures greater than 200 °C.

Ceramic encapsulation materials have great thermal stability, but their poor conformability and flexibility may readily induce fractures in the encapsulating films, particularly after repeated tensile and bending stresses, which would amplify oxygen penetration and hasten performance deterioration of the system. As a result, an encapsulating (or coating) material that is conformal, flexible, and thermally stable is needed for use in electronic systems.

With its excellent chemical and thermal stability, hexagonal boron nitride (h-BN) is considered a suitable encapsulation material against oxidation for carbon-based electronic systems.

What is the Best Approach for Coating with Hexagonal Boron Nitride?

The deposition of h-BN layers on material surfaces can be accomplished via pulsed laser deposition; however, it is hampered by greater expenses and poor crystal quality. Another alternate encapsulating strategy is to wrap material surfaces with h-BN powder dispersion. Unfortunately, large area homogeneity is hard to attain, and the thick h-BN encapsulation films frequently influence the inherent elasticity of the material to be enclosed.

Mechanically exfoliating from bulk h-BN and distributing from CVD-grown thin-layer h-BN are both successful methods for obtaining good quality h-BN atomic films, which have been extensively employed to enclose different devices based on 2D materials. Nonetheless, both techniques are restricted in scalability because of the significant difficulties in realizing large-area intact exfoliation or transference.

Complete-surface, conforming encapsulation for delicately structured items, such as complete-surface encapsulation for fiber-like materials, poses more complications and needs for encapsulation methods and has not been adequately addressed by existing methodologies.

Bringing out the Best of Graphene Glass Fiber Fabric

Lately, graphene glass fiber fabric (GGFF), a sophisticated graphene-based electrothermal material, has been successfully created. GGFF demonstrates remarkable electrothermal behavior by incorporating graphene’s high conductance of heat and electricity with the glass fiber’s outstanding mechanical strength and elasticity.

As a result of oxidation, graphene cannot exist at temperatures over 500 °C in the environment. Therefore, the GGFF electrothermal system’s long-term steady operating temperature is severely constrained.

Effective encapsulating techniques for carbon-based electronic systems, particularly those with complicated architectures including this fiber-like GGFF, are promptly required, which cannot be provided by typical exfoliating or transferring processes. The packaging of pliable electronics without sacrificing their elasticity complicates the encapsulation process even further.

Highlights of the Study

In this study, aimed toward the GGFF electrothermal device, on-site CVD production of nanometric h-BN films was used to provide flexible, complete-surface, conforming encapsulation for every fiber in the sizable fabric.

The h-BN-enclosed GGFF (h-BN/GGFF) demonstrated improved resistance to oxidation in the environment, with sustained heat durations up to one order of magnitude greater than plain GGFF without compromising the excellent elasticity and strength of the fabric. The h-BN coating had no effect on GGFF’s remarkable infrared radiation capacity, which is a crucial feature used in radiative heat control.

Theoretical models identified additional processes for h-BN/ GGFF’s increased resistance against oxidation. The coating of h-BN may dramatically enhance the adsorptive energy and decrease the adsorbing life of oxygen, both of which are important in oxidizing graphene.

This research presented a flexible, complete-surface, and conforming encapsulation approach aimed at the fiber-like graphene electrothermal system, which can be scaled up and extended to other carbon-based materials and two-dimensional materials, including devices with complex shapes, promoting the advancement of nanoscale electronics in harsh environments.

News

Breakthrough in Antimicrobial Technology with Cinnamon-Based Nanokiller

The need for innovative antimicrobial agents has become increasingly urgent due to the rise of antibiotic-resistant pathogens and the persistent threat of infections acquired during hospital stays. Traditional antibiotics and antiseptics are often ineffective [...]

The Silent Battle Within: How Your Organs Choose Between Mom and Dad’s Genes

Research reveals that selective expression of maternal or paternal X chromosomes varies by organ, driven by cellular competition. A new study published today (July 26) in Nature Genetics by the Lymphoid Development Group at the MRC [...]

Study identifies genes increasing risk of severe COVID-19

Whether or not a person becomes seriously ill with COVID-19 depends, among other things, on genetic factors. With this in mind, researchers from the University Hospital Bonn (UKB) and the University of Bonn, in [...]

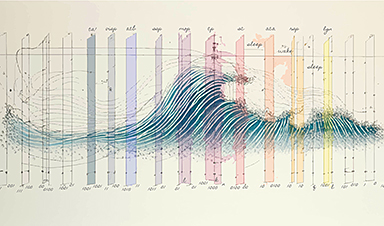

Small regions of the brain can take micro-naps while the rest of the brain is awake and vice versa

Sleep and wake: They're totally distinct states of being that define the boundaries of our daily lives. For years, scientists have measured the difference between these instinctual brain processes by observing brain waves, with [...]

Redefining Consciousness: Small Regions of the Brain Can Take Micro-Naps While the Rest of the Brain Is Awake

The study broadly reveals how fast brain waves, previously overlooked, establish fundamental patterns of sleep and wakefulness. Scientists have developed a new method to analyze sleep and wake states by detecting ultra-fast neuronal activity [...]

AI Reveals Health Secrets Through Facial Temperature Mapping

Researchers have found that different facial temperatures correlate with chronic illnesses like diabetes and high blood pressure, and these can be detected using AI with thermal cameras. They highlight the potential of this technology [...]

Breakthrough in aging research: Blocking IL-11 extends lifespan and improves health in mice

In a recent study published in the journal Nature, a team of researchers used murine models and various pharmacological and genetic approaches to examine whether pro-inflammatory signaling involving interleukin (IL)-11, which activates signaling molecules such [...]

Promise for a universal influenza vaccine: Scientists validate theory using 1918 flu virus

New research led by Oregon Health & Science University reveals a promising approach to developing a universal influenza vaccine—a so-called "one and done" vaccine that confers lifetime immunity against an evolving virus. The study, [...]

New Projects Aim To Pioneer the Future of Neuroscience

One study will investigate the alterations in brain activity at the cellular level caused by psilocybin, the psychoactive substance found in “magic mushrooms.” How do neurons respond to the effects of magic mushrooms? What [...]

Decoding the Decline: Scientific Insights Into Long COVID’s Retreat

Research indicates a significant reduction in long COVID risk, largely due to vaccination and the virus’s evolution. The study analyzes data from over 441,000 veterans, showing lower rates of long COVID among vaccinated individuals compared [...]

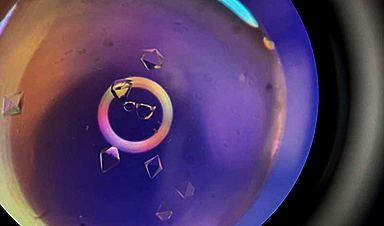

Silicon Transformed: A Breakthrough in Laser Nanofabrication

A new method enables precise nanofabrication inside silicon using spatial light modulation and laser pulses, creating advanced nanostructures for potential use in electronics and photonics. Silicon, the cornerstone of modern electronics, photovoltaics, and photonics, [...]

Caught in the actinium: New research could help design better cancer treatments

The element actinium was first discovered at the turn of the 20th century, but even now, nearly 125 years later, researchers still don't have a good grasp on the metal's chemistry. That's because actinium [...]

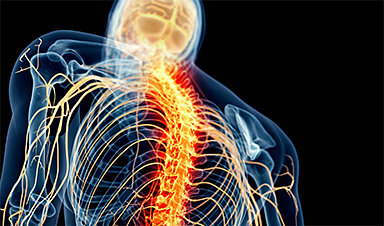

Innovative Light-Controlled Drugs Could Revolutionize Neuropathic Pain Treatment

A team of researchers from the Institute for Bioengineering of Catalonia (IBEC) has developed light-activated derivatives of the anti-epileptic drug carbamazepine to treat neuropathic pain. Light can be harnessed to target drugs to specific [...]

Green Gold: Turning E-Waste Into a Treasure Trove of Rare Earth Metals

Scientists are developing a process inspired by nature that efficiently recovers europium from old fluorescent lamps. The approach could lead to the long-awaited recycling of rare earth metals. A small molecule that naturally serves [...]

Cambridge Study: AI Chatbots Have an “Empathy Gap,” and It Could Be Dangerous

A new study suggests a framework for “Child Safe AI” in response to recent incidents showing that many children perceive chatbots as quasi-human and reliable. A study has indicated that AI chatbots often exhibit [...]

Nanoparticle-based delivery system could offer treatment for diabetics with rare insulin allergy

Up to 3% of people with diabetes have an allergic reaction to insulin. A team at Forschungszentrum Jülich has now studied a method that could be used to deliver the active substance into the [...]