The precise, continuous monitoring of pollutants such as nitrogen oxides (NOx) in high humidity is a tough challenge for low-cost and stretchable gas sensors.

A recent article published in Microsystems & Nanoengineering describes the design and implementation of a novel, moisture-resistant, and wearable NOx gas sensor based on laser-induced graphene (LIG) that has proven successful in monitoring the environment and classifying individuals with breathing problems.

Importance of Nitrogen Oxides (NOx) Detection

Nitrogen oxides (collectively referred to as NOx) produced by combustion processes and petroleum refineries are significant air pollutants that cause bronchitis, asthma, and heart-aggravating disorders.

Nitric oxide (NO), a key biomarker for pulmonary inflammation, is of great relevance for the non-invasive detection and treatment of respiratory disorders such as lung cancer and ventilator-associated pneumonitis. This is because the level of nitric oxide in exhaled breath of asthma patients surpasses hundreds of parts per billion (ppb), but this amount is less than a few tens of ppb in healthy individuals.

Consequently, it is of the utmost significance to create new, inexpensive, and dependable gas sensors for continuously and precisely detecting nitrogen oxide (NOx) in human breath.

Wearable Graphene-based Gas Sensors for Detection of NOx

Several technologies using nanoparticles such as metal oxides, graphene, carbon nanotubes, and conductive polymers have been developed to detect NOx in human breath.

In contrast to the electrolytic cells, field-effect semiconductors and other conventional gas sensors, wearable NOx gas sensors based on graphene exhibit low noise and good mechanical robustness.

Wearable electronic devices can gather electrical, biochemical, thermal, physical, and biological information for comprehensive health management. The growing interest in personalized air quality assessment and breath testing has also increased the need for wearable graphene-based gas sensors that can detect different harmful chemicals, such as nitrogen oxides (NOx), precisely and continuously.

Graphene-based gas sensors with unmodified surfaces show low accuracy due to the absence of active sites. To tackle this issue, the newly discovered 3D laser-induced graphene (LIG) can be utilized because it provides a large number of active sites on the surface for gas-solid interactions.

Relative Humidity: A Major Limitation in Accurate Gas Sensing

As water particles populate the active surface functional sites of sensing nanomaterials, the relative humidity (RH) significantly affects the absorption and equilibrium mechanisms of the target gas, resulting in substantial response changes in breath samples with an RH between 50 and 95 percent.

The impact of relative humidity on gas sensing can be minimized by utilizing coated integrated heating components, hydrophobic self-assembled monolayers (SAMs), or electronic nose algorithms. However, these technologies often increase the sophistication and expense of gas sensor production.

Therefore, it is crucial to establish a simple method for designing and fabricating moisture-resistant NOx gas sensors with a large response rate, quick response/recovery, and a low limit of detection (LOD) for monitoring local air pollution and analyzing breath samples for disease diagnoses.

A Novel Moisture-Resistant LIG-based NOx Gas Sensor

In this study, the researchers created a novel, flexible, and moisture-resistant LIG-based NOx gas sensor by sandwiching the LIG sensing area between a semi-permeable polydimethylsiloxane (PDMS) layer and a flexible elastomeric platform.

The flexible, extremely sensitive, and selective LIG-based gas sensor is composed of a straight LIG sensing area and a serpentine electrode on a soft elastomeric platform. The LIG sensing region has a much narrower width (150 micro-meter) than the electrodes to produce substantially stronger resistance and concentrated Joule heating in the sensing zone,

The rapid and low-cost manufacturing method is also scalable, promising rapid large-scale production for commercial applications in the future.

Key Developments of the Research

At room temperature, the as-prepared gas sensor displays a high response rate, rapid response/recovery, and an ultralow limit of detection (LOD) for various nitrogen oxides (NOx). By adjusting laser processing parameters such as laser intensity, image frequency, and defocus distance, the laser direct writing method can produce LIG sensing zones with varying morphologies.

This unique water-resistant LIG-based gas sensor can detect the outside air quality at various times of the day by combining a high stretchability of 30 percent and a moisture-resistant capability against a relative humidity of 90 percent. In addition, it can promptly evaluate clinical breath samples to properly distinguish between patients with respiratory illnesses and healthy human beings.

News

Team finds flawed data in recent study relevant to coronavirus antiviral development

The COVID pandemic illustrated how urgently we need antiviral medications capable of treating coronavirus infections. To aid this effort, researchers quickly homed in on part of SARS-CoV-2's molecular structure known as the NiRAN domain—an [...]

Drug-Coated Neural Implants Reduce Immune Rejection

Summary: A new study shows that coating neural prosthetic implants with the anti-inflammatory drug dexamethasone helps reduce the body’s immune response and scar tissue formation. This strategy enhances the long-term performance and stability of electrodes [...]

Scientists discover cancer-fighting bacteria that ‘soak up’ forever chemicals in the body

A family of healthy bacteria may help 'soak up' toxic forever chemicals in the body, warding off their cancerous effects. Forever chemicals, also known as PFAS (per- and polyfluoroalkyl substances), are toxic chemicals that [...]

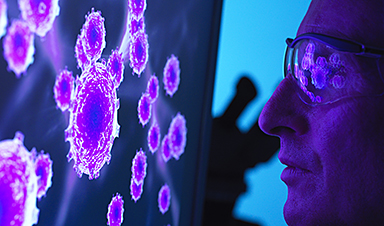

Johns Hopkins Researchers Uncover a New Way To Kill Cancer Cells

A new study reveals that blocking ribosomal RNA production rewires cancer cell behavior and could help treat genetically unstable tumors. Researchers at the Johns Hopkins Kimmel Cancer Center and the Department of Radiation Oncology and Molecular [...]

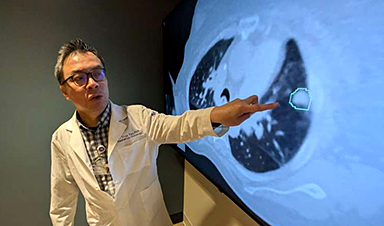

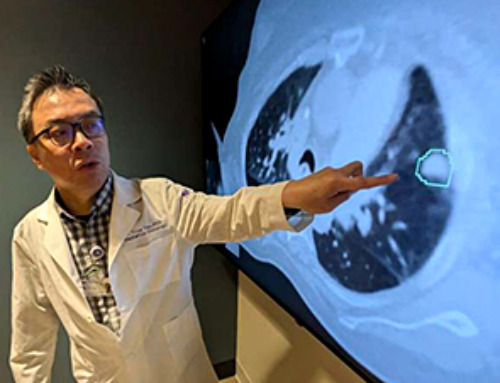

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]

Aging Spreads Through the Bloodstream

Summary: New research reveals that aging isn’t just a local cellular process—it can spread throughout the body via the bloodstream. A redox-sensitive protein called ReHMGB1, secreted by senescent cells, was found to trigger aging features [...]

AI and nanomedicine find rare biomarkers for prostrate cancer and atherosclerosis

Imagine a stadium packed with 75,000 fans, all wearing green and white jerseys—except one person in a solid green shirt. Finding that person would be tough. That's how hard it is for scientists to [...]

Are Pesticides Breeding the Next Pandemic? Experts Warn of Fungal Superbugs

Fungicides used in agriculture have been linked to an increase in resistance to antifungal drugs in both humans and animals. Fungal infections are on the rise, and two UC Davis infectious disease experts, Dr. George Thompson [...]

Scientists Crack the 500-Million-Year-Old Code That Controls Your Immune System

A collaborative team from Penn Medicine and Penn Engineering has uncovered the mathematical principles behind a 500-million-year-old protein network that determines whether foreign materials are recognized as friend or foe. How does your body [...]

Team discovers how tiny parts of cells stay organized, new insights for blocking cancer growth

A team of international researchers led by scientists at City of Hope provides the most thorough account yet of an elusive target for cancer treatment. Published in Science Advances, the study suggests a complex signaling [...]

Nanomaterials in Ophthalmology: A Review

Eye diseases are becoming more common. In 2020, over 250 million people had mild vision problems, and 295 million experienced moderate to severe ocular conditions. In response, researchers are turning to nanotechnology and nanomaterials—tools that are transforming [...]

Natural Plant Extract Removes up to 90% of Microplastics From Water

Researchers found that natural polymers derived from okra and fenugreek are highly effective at removing microplastics from water. The same sticky substances that make okra slimy and give fenugreek its gel-like texture could help [...]

Instant coffee may damage your eyes, genetic study finds

A new genetic study shows that just one extra cup of instant coffee a day could significantly increase your risk of developing dry AMD, shedding fresh light on how our daily beverage choices may [...]