Methacrylate-based materials are often used in bone cement and dental resins. However, they have high failure rates as they undergo damage within ten years, impacting the quality of patient’s life and increasing healthcare costs.

Although replacing methacrylate-based materials with self-healing resins and bone cement could increase lifespan, reduce costs, and enhance patient outcomes, the practical applicability of these materials is limited due to their low efficacy and toxicity. An article published in the journal ACS Omega addressed this issue by developing a dual nanocapsule-based self-healing system.

Two polyurethane (PU) shell-based nanocapsules were synthesized: an initiator capsule containing benzoyl peroxide and butylated hydroxytoluene and a monomer capsule containing triethylene glycol dimethacrylate.

Resins with these nanocapsules were tested under tension until failure, followed by assembling the fractured surfaces. 33% of samples showed self-healing behavior and could be reloaded for testing under tension. The capsules and their components were biocompatible with Caco-2 cell lines, suggesting in vivo tolerance of the prepared nanocapsules.

Nanocapsules as Self-Healing Materials

Self-healing materials, when damaged through thermal, mechanical, and ballistic effects can heal and restore materials to their original properties. Few materials intrinsically possess this self-healing ability, which is a valuable characteristic in designing systems since it effectively expands the lifetime use of the product and has desirable economic and human safety attributes.

These self-healing materials could be useful in methacrylate-based systems, including dental resins and bone cement. Aseptic loosening of bone cement by forming cracks may trigger inflammation and bone resorption, requiring expensive surgical intervention. Although modern dental resins prevent any effects on the environment and health with mercury, their poor durability causing implant damage within ten years, has increased the cost of dental care.

Nanocapsules are hollow sphere structures with submicrometer dimensions. Such nanocapsules can accommodate large quantities of guest molecules within their empty core domain. These materials could be helpful in applications in the fields of biological chemistry, synthesis, and catalysis.

Polymeric nanocapsules with a multitude of applications have already been proposed, such as confined reaction vessels, drug carriers, protective shells for cells or enzymes, transfection vectors in gene therapy, carrier systems in heterogeneous catalysis, dye dispersants, or as materials for removal of contaminated waste.

Methacrylate-based nanocapsules are easy to implement for self-healing properties in both dental resins and bone cement due to their filler particles that enhance the material’s mechanical properties. Initially, the nanocapsules simply act as an additional filler. However, when a crack propagates through the material, it breaks and releases components into the crack through capillary action that polymerizes later to heal the matrix.

Biocompatible Nanocapsules with Self-Healing Capacity

Nanocapsules were hypothesized to undergo a robust self-healing process with less impact on the mechanical properties than larger particles. Thus, the present work aimed to investigate single and dual nanocapsule systems based on PU and nontoxic components.

The impact of the prepared single and dual nanocapsules on the self-healing process of methacrylate resins was determined by synthesizing PU nanocapsules, which encapsulate either the initiator or monomer. Furthermore, the mechanical testing and biocompatibility analysis determined the system’s feasibility as a self-healing additive for bone cement and dental resins.

The monomer used here was TEGDMA, with a long shelf-life and quick polymerization capability. The healing liquid was expected to have low viscosity to flow through cracks of resin and fill it. Hence, TEGDMA was previously used as a dental monomer.

Here, using butylated hydroxytoluene (BHT) along with benzyl peroxide (BPO) prevented the formation of free radicals before their release from the capsule. Thus, the initiator component based on BPO and BHT increased the stability of the dual-capsule-based self-healing system.

The fracturing of nanocapsules was an important finding of the present work since their rupture was the basis for the self-healing process. While a too-thick shell did not allow the capsule to rupture, a too-thin shell resulted in fragile nanocapsules.

Conclusion

Overall, PU nanocapsule encapsulating TEGDMA monomer was embedded into an epoxy resin. These embedded resins were compared with their blank counterparts to determine the effects of monomer nanocapsules on the resin’s mechanical properties.

Comparing the elastic modulus, yield stress, ultimate tensile stress, and strain to fracture indicated that the resin without monomer capsules was stronger than the resin with monomer capsules. The monomer nanocapsules cracked during the resin fracture, proving the self-healing effect of the nanocapsules in resins.

Moreover, premature cracking of resins in the gastrointestinal tract did not cause any detrimental effects on the patient, suggesting the biocompatibility of the developed self-healing system. Furthermore, a small degree of self-healing capacity was observed in the resins with monomer nanocapsules, unencapsulated BPO, and the resins with monomer nanocapsules, and initiator capsules.

Team finds flawed data in recent study relevant to coronavirus antiviral development

The COVID pandemic illustrated how urgently we need antiviral medications capable of treating coronavirus infections. To aid this effort, researchers quickly homed in on part of SARS-CoV-2's molecular structure known as the NiRAN domain—an [...]

Drug-Coated Neural Implants Reduce Immune Rejection

Summary: A new study shows that coating neural prosthetic implants with the anti-inflammatory drug dexamethasone helps reduce the body’s immune response and scar tissue formation. This strategy enhances the long-term performance and stability of electrodes [...]

Scientists discover cancer-fighting bacteria that ‘soak up’ forever chemicals in the body

A family of healthy bacteria may help 'soak up' toxic forever chemicals in the body, warding off their cancerous effects. Forever chemicals, also known as PFAS (per- and polyfluoroalkyl substances), are toxic chemicals that [...]

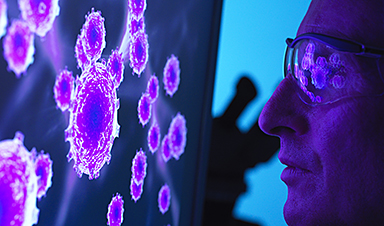

Johns Hopkins Researchers Uncover a New Way To Kill Cancer Cells

A new study reveals that blocking ribosomal RNA production rewires cancer cell behavior and could help treat genetically unstable tumors. Researchers at the Johns Hopkins Kimmel Cancer Center and the Department of Radiation Oncology and Molecular [...]

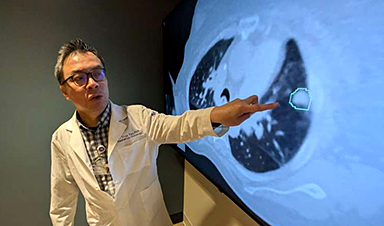

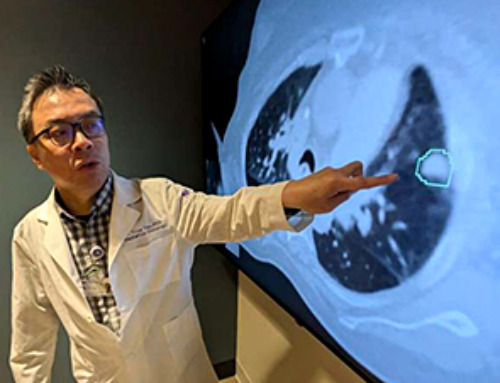

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]

Aging Spreads Through the Bloodstream

Summary: New research reveals that aging isn’t just a local cellular process—it can spread throughout the body via the bloodstream. A redox-sensitive protein called ReHMGB1, secreted by senescent cells, was found to trigger aging features [...]

AI and nanomedicine find rare biomarkers for prostrate cancer and atherosclerosis

Imagine a stadium packed with 75,000 fans, all wearing green and white jerseys—except one person in a solid green shirt. Finding that person would be tough. That's how hard it is for scientists to [...]

Are Pesticides Breeding the Next Pandemic? Experts Warn of Fungal Superbugs

Fungicides used in agriculture have been linked to an increase in resistance to antifungal drugs in both humans and animals. Fungal infections are on the rise, and two UC Davis infectious disease experts, Dr. George Thompson [...]

Scientists Crack the 500-Million-Year-Old Code That Controls Your Immune System

A collaborative team from Penn Medicine and Penn Engineering has uncovered the mathematical principles behind a 500-million-year-old protein network that determines whether foreign materials are recognized as friend or foe. How does your body [...]

Team discovers how tiny parts of cells stay organized, new insights for blocking cancer growth

A team of international researchers led by scientists at City of Hope provides the most thorough account yet of an elusive target for cancer treatment. Published in Science Advances, the study suggests a complex signaling [...]

Nanomaterials in Ophthalmology: A Review

Eye diseases are becoming more common. In 2020, over 250 million people had mild vision problems, and 295 million experienced moderate to severe ocular conditions. In response, researchers are turning to nanotechnology and nanomaterials—tools that are transforming [...]

Natural Plant Extract Removes up to 90% of Microplastics From Water

Researchers found that natural polymers derived from okra and fenugreek are highly effective at removing microplastics from water. The same sticky substances that make okra slimy and give fenugreek its gel-like texture could help [...]

Instant coffee may damage your eyes, genetic study finds

A new genetic study shows that just one extra cup of instant coffee a day could significantly increase your risk of developing dry AMD, shedding fresh light on how our daily beverage choices may [...]