Self-healable ionic sensing materials with fatigue resistance are imperative in robotics and soft electronics for extended service life. The existing artificial ionic skins with self-healing capacity were prepared by network reconfiguration, constituting low-energy amorphous polymer chains. Consequently, these materials suffer from a low fatigue threshold and are susceptible to crack propagation.

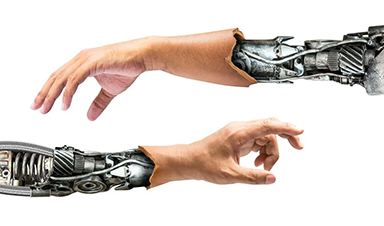

In an article published in the journal Nature Communications, a self-healable, fatigue-free hybrid ionic skin was engineered. Ruggedness was imparted by incorporating an elastic nanomesh that was a complex network of nanofibers. Thus, the engineered ionic skin mimicked the human skin with a repairable interwoven structure based on nanofibers.

The designed hybrid ionic skin exhibited a fatigue threshold of 2950 joules per square meter while conserving stretchability, skin-like compliance, and strain adaptive stiffening behavior. The nanofibers in the material endowed the ionic matrix with moisture breathing capacity due to the induced tension, leading to a gauge factor of 66.8, which was higher than the existing artificial ionic skins. The present concept created a new path toward durable ion-conducting materials that mimicked the incomparable combinatory properties of human skin.

Integrating Nanofibers into Artificial Skin

Human skin is a multifunctional organ that is self-healing and protective with good sensing capacity. Various artificial skins were developed based on the properties and functionalities approximating those of natural skin. To this end, stretchability, conductivity, toughness, softness, healing ability, and durability are desirable in designing materials for soft robotics and human-machine interface applications.

Although self-healing capacity in these materials permits a long service life, their resistance against crack propagation during high fatigue loads further begets robustness in them. Incorporating physical crosslinks into the ion-conducting network causes chain rearrangement leading to network reconfiguration.

The ion-rich nanofibrous yet repairable structure of human skin reconciles the interchange between fatigue resistance and healing capacity, defined by a soft interwoven elastic matrix enveloping the stiff collagen fibril scaffold. The healing of human skin is based on dermal fibroblasts and repairing the crack tip at the collagen nanofibrils imparting high fracture toughness. Thus, the human skin can withstand tear fractures and deformations like muscles.

Nanofibers have diameters between 1 nanometer and 1 micrometer and are made from synthetic or natural materials. Nanofibers are commonly obtained via the electrospinning technique and resemble the natural extracellular matrix (ECM). The polymer-based nanofibers have a large surface area-to-volume ratio, high porosity, appreciable mechanical strength, and flexibility.

These properties of nanofibers have a significant effect on cell adhesion, proliferation, and differentiation, as reported in previous studies. Hence matrices based on nanofibers are explored as scaffolds in tissue engineering.

Nanofiber Reinforced Artificial Ionic Skin

In the present work, a high-energy, elastic, and self-healable nanomesh scaffold was embedded into another self-healable soft ionic matrix to design an artificial sensing ionic skin. This hybrid structure showed high fracture energy of 16.3 kilojoules per square meter, fatigue threshold of 2950 joules per square meter, 680% stretchability, and 67.5 megapascals of strain-stiffening response.

The tension-induced rearrangement of nanofibers caused reversible moisture breathing of the hygroscopic ionic matrix and led to a gauge factor of 66.8 (higher than the existing artificial skin materials) for the ionic conductors that are intrinsically stretchable.

Moreover, such hybrid ionic skin based on nanofibers had a few intriguing properties that mimicked the natural human skin, including self-healing efficiency of up to 85%, modulus of approximately 1.8 megapascals, 37 times enhanced strain-adaptive stiffness, 0.11 siemens per centimeter of ionic conductivity, and superior strain sensation. The prepared hybrid ionic skin was adhesive, transparent, and ambiently stable.

Thus, the reported artificial ionic skin resembled the human skin in terms of sensing and mechanical properties and had potential applications in durable sensors for utilization in human-machine interfaces and wearable electronics.

Conclusion

To conclude, transparent hybrid ionic skin based on nanofibers was designed using elastic polyurethane (PU) nanomesh, composed of a network of nanofibers with self-healing capacity and a supramolecular ionic matrix with a high modulus ratio.

The hybrid ionic skin was endowed with desirable properties, including softness (modulus approximately 1.8 megapascals), self-healing capacity (up to 85%), stretchability (680%), fatigue resistance (approximately 2950 joules per square meters), and strain-adaptive stiffening (37 times enhanced stiffness).

The high gauge factor of 66.8, which is the strain-sensing parameter, was due to the induced tension that led to a rearrangement of nanofiber’s alignment resulting in a reversible moisture breathing effect in a hygroscopic ionic matrix driven by water-sensitive ionic complexations.

In concurrence with its adhesiveness, transparency, and stability at room temperature, the designed ionic skin demonstrated its potential as a durable sensor with high sensitivity and applicability in wearable electronics.

News

Johns Hopkins Researchers Uncover a New Way To Kill Cancer Cells

A new study reveals that blocking ribosomal RNA production rewires cancer cell behavior and could help treat genetically unstable tumors. Researchers at the Johns Hopkins Kimmel Cancer Center and the Department of Radiation Oncology and Molecular [...]

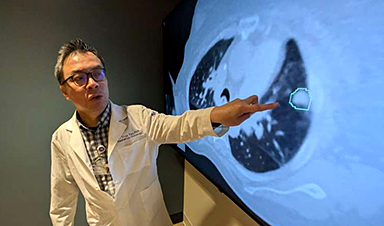

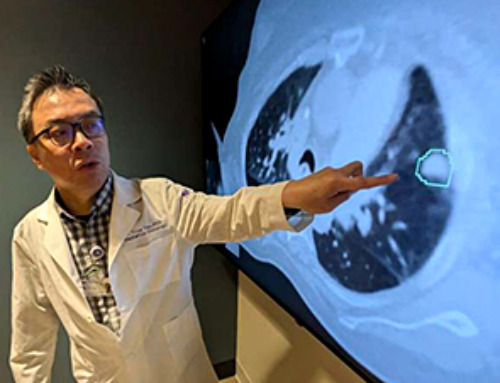

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]

Aging Spreads Through the Bloodstream

Summary: New research reveals that aging isn’t just a local cellular process—it can spread throughout the body via the bloodstream. A redox-sensitive protein called ReHMGB1, secreted by senescent cells, was found to trigger aging features [...]

AI and nanomedicine find rare biomarkers for prostrate cancer and atherosclerosis

Imagine a stadium packed with 75,000 fans, all wearing green and white jerseys—except one person in a solid green shirt. Finding that person would be tough. That's how hard it is for scientists to [...]

Are Pesticides Breeding the Next Pandemic? Experts Warn of Fungal Superbugs

Fungicides used in agriculture have been linked to an increase in resistance to antifungal drugs in both humans and animals. Fungal infections are on the rise, and two UC Davis infectious disease experts, Dr. George Thompson [...]

Scientists Crack the 500-Million-Year-Old Code That Controls Your Immune System

A collaborative team from Penn Medicine and Penn Engineering has uncovered the mathematical principles behind a 500-million-year-old protein network that determines whether foreign materials are recognized as friend or foe. How does your body [...]

Team discovers how tiny parts of cells stay organized, new insights for blocking cancer growth

A team of international researchers led by scientists at City of Hope provides the most thorough account yet of an elusive target for cancer treatment. Published in Science Advances, the study suggests a complex signaling [...]

Nanomaterials in Ophthalmology: A Review

Eye diseases are becoming more common. In 2020, over 250 million people had mild vision problems, and 295 million experienced moderate to severe ocular conditions. In response, researchers are turning to nanotechnology and nanomaterials—tools that are transforming [...]

Natural Plant Extract Removes up to 90% of Microplastics From Water

Researchers found that natural polymers derived from okra and fenugreek are highly effective at removing microplastics from water. The same sticky substances that make okra slimy and give fenugreek its gel-like texture could help [...]

Instant coffee may damage your eyes, genetic study finds

A new genetic study shows that just one extra cup of instant coffee a day could significantly increase your risk of developing dry AMD, shedding fresh light on how our daily beverage choices may [...]

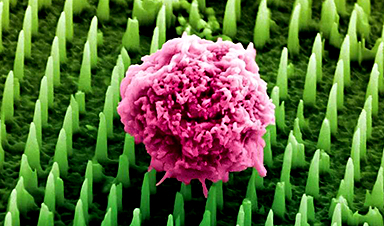

Nanoneedle patch offers painless alternative to traditional cancer biopsies

A patch containing tens of millions of microscopic nanoneedles could soon replace traditional biopsies, scientists have found. The patch offers a painless and less invasive alternative for millions of patients worldwide who undergo biopsies [...]

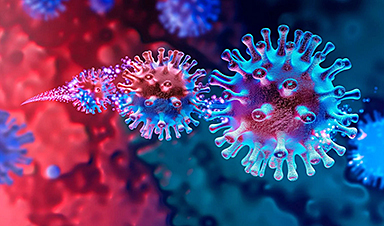

Small antibodies provide broad protection against SARS coronaviruses

Scientists have discovered a unique class of small antibodies that are strongly protective against a wide range of SARS coronaviruses, including SARS-CoV-1 and numerous early and recent SARS-CoV-2 variants. The unique antibodies target an [...]

Controlling This One Molecule Could Halt Alzheimer’s in Its Tracks

New research identifies the immune molecule STING as a driver of brain damage in Alzheimer’s. A new approach to Alzheimer’s disease has led to an exciting discovery that could help stop the devastating cognitive decline [...]