In an article published in the journal Science of the Total Environment, researchers have highlighted the significance and potential risks associated with the release of nanoparticles from coal-fired power plants. Applying the single-particle inductively coupled plasma mass technique, the particle size and particle number concentration (PNC) of conventional metal-containing nanoparticles (Fe and Ti containing nanoparticles) were investigated.

Nanoparticles and Associated Properties

Nanoparticles (NPs) are microscopic molecules with less than 100 nm aerodynamic dimensions in one direction. Although their size might be overlooked, they are recognized as the most significant and abundant PM elements. Furthermore, the safety of nanoparticles is influenced mainly by their dimension and particle number concentrations.

However, since existing air-quality monitoring techniques focus on size, it is impossible to precisely estimate nanoparticles based on concentration. Nanoparticles also have tiny impacts, large specific surface regions, and complicated chemical compositions. As a consequence, they can penetrate the respiratory pathways and cause pain.

Coal Combustion By-Products

Coal fly ash (CFA) is perhaps the most significant coal combustion by-product (CCP) of coal-fired power plants (CFPPs) and has become China’s principal industrial debris. To meet the strict limits of extremely low emissions, all coal-fired power stations in China need to be fitted with different particulate emission control devices (PECDs) that capture the copious particulates created by pulverized coal burning.

High frequency driven multi-stage condensers, fabric filters (FFs), and electrically charged incorporated charcoal filters are the most common particulate emission control devices. Nevertheless, neither of these approaches has considered the elimination of nanoparticles, particularly in terms of particle number concentrations.

Quantitative Analysis of the Metal-Containing Nanoparticles

The first statistical investigation of metal-containing nanoparticles in coal fly ashes gathered in the final ash collection chutes of particle emission control systems generated by reduced coal burning from various sources in China was recently conducted.

It was revealed that metal-containing nanoparticles comprising Fe and Ti were the primary and typical metal-containing nanoparticles in coal combustion particles, which may offer significant dangers to human breathing. Furthermore, Fe- and Ti-containing nanoparticles in coal fly ashes have been discovered using different methods.

Combustion-derived metallic nanoparticles, particularly Fe3O4-nanoparticles, have been found in human blood, empyema, and the brain, suggesting a link to neurological illnesses such as Alzheimer’s. Furthermore, the TiO2 and Magnéli phases prevalent in coal fly ashes might cause substantial cellular disorders and reduced pulmonary function.

Nevertheless, numerical analysis of those coal combustion-derived nanomaterials, such as Fe- and Ti-containing nanomaterials, is still absent, which is critical for gaining a thorough knowledge of the possible health concerns posed by coal fly ashes.

Moreover, the elimination of coal-combustion-derived nanoparticles in coal fly ashes captured by particulate emission control units has not been explored during coal burning, particularly for the coal fly ashes trapped for each phase. More crucially, no quantitative research on the particle number ratios and dimensions of the eventual metal-containing nanoparticles that may be emitted into the environment has been disclosed.

Key Objectives of the Research

The particular aims of this research included quantifying the microstructures of Fe- and Ti containing nanoparticles and their particle number concentrations (PNCs) in CFAs recorded at every phase of particulate emission control units, comparing the removal rate of these nanoparticles by various multi-stage particulate emission control devices, and quantifying Fe- and Ti containing nanoparticle emission levels in all CCPs.

A better comprehension of the properties of classic nanoparticles found in coal fly ashes intercepted by multi-stage particulate emission control devices could be done. The final nanoparticle emissions into the environment would provide crucial input for enhancing coal-burning activities and assessing health-related dangers.

Highlights of the Study

The numerical classification of the particle size and concentration of coal combustion-sourced nanoparticles, particularly the dispersion of nanoparticles in coal fly ashes at every phase of various particulate emission control units, is considered critical for a detailed understanding of nanoparticle absorptivity and evaluation of nanoparticle emission levels by different particle combustion control systems.

This research was the first comprehensive analysis of the issue. It was discovered that significant nanoparticles in coal fly ashes were seized in every phase of the various particulate combustion control systems. As the configuration phase of the particulate emission control devices continued to increase, so did the particle number concentration levels of Fe- and Ti-containing nanoparticles.

As a result, it can be concluded that, in contrast, condensers account for 75-80% of particulate emission control devices in use in Chinese power stations, electrostatic-fabric-integrated precipitators (EFIPs) outperform electrostatic precipitators and fabric filtration in metal-containing nanoparticle clean-up. This result established a foundation for the high-efficiency and sustainable coal exploitation in power reactors using metal-containing nanoparticles.

News

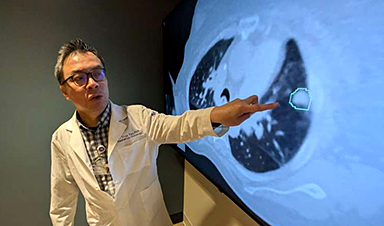

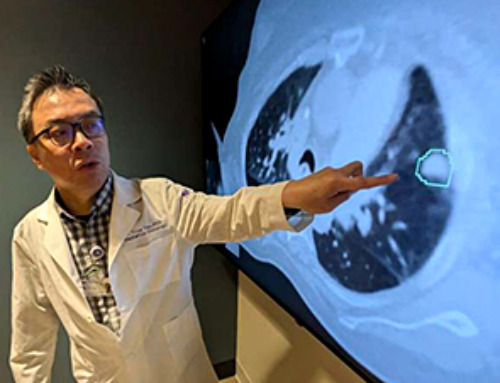

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]

Aging Spreads Through the Bloodstream

Summary: New research reveals that aging isn’t just a local cellular process—it can spread throughout the body via the bloodstream. A redox-sensitive protein called ReHMGB1, secreted by senescent cells, was found to trigger aging features [...]

AI and nanomedicine find rare biomarkers for prostrate cancer and atherosclerosis

Imagine a stadium packed with 75,000 fans, all wearing green and white jerseys—except one person in a solid green shirt. Finding that person would be tough. That's how hard it is for scientists to [...]

Are Pesticides Breeding the Next Pandemic? Experts Warn of Fungal Superbugs

Fungicides used in agriculture have been linked to an increase in resistance to antifungal drugs in both humans and animals. Fungal infections are on the rise, and two UC Davis infectious disease experts, Dr. George Thompson [...]

Scientists Crack the 500-Million-Year-Old Code That Controls Your Immune System

A collaborative team from Penn Medicine and Penn Engineering has uncovered the mathematical principles behind a 500-million-year-old protein network that determines whether foreign materials are recognized as friend or foe. How does your body [...]

Team discovers how tiny parts of cells stay organized, new insights for blocking cancer growth

A team of international researchers led by scientists at City of Hope provides the most thorough account yet of an elusive target for cancer treatment. Published in Science Advances, the study suggests a complex signaling [...]

Nanomaterials in Ophthalmology: A Review

Eye diseases are becoming more common. In 2020, over 250 million people had mild vision problems, and 295 million experienced moderate to severe ocular conditions. In response, researchers are turning to nanotechnology and nanomaterials—tools that are transforming [...]

Natural Plant Extract Removes up to 90% of Microplastics From Water

Researchers found that natural polymers derived from okra and fenugreek are highly effective at removing microplastics from water. The same sticky substances that make okra slimy and give fenugreek its gel-like texture could help [...]

Instant coffee may damage your eyes, genetic study finds

A new genetic study shows that just one extra cup of instant coffee a day could significantly increase your risk of developing dry AMD, shedding fresh light on how our daily beverage choices may [...]

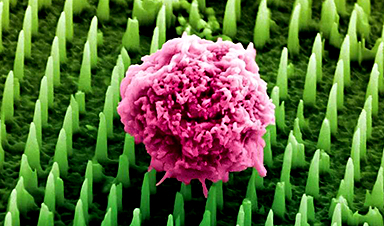

Nanoneedle patch offers painless alternative to traditional cancer biopsies

A patch containing tens of millions of microscopic nanoneedles could soon replace traditional biopsies, scientists have found. The patch offers a painless and less invasive alternative for millions of patients worldwide who undergo biopsies [...]

Small antibodies provide broad protection against SARS coronaviruses

Scientists have discovered a unique class of small antibodies that are strongly protective against a wide range of SARS coronaviruses, including SARS-CoV-1 and numerous early and recent SARS-CoV-2 variants. The unique antibodies target an [...]

Controlling This One Molecule Could Halt Alzheimer’s in Its Tracks

New research identifies the immune molecule STING as a driver of brain damage in Alzheimer’s. A new approach to Alzheimer’s disease has led to an exciting discovery that could help stop the devastating cognitive decline [...]

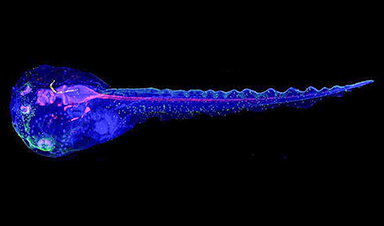

Cyborg tadpoles are helping us learn how brain development starts

How does our brain, which is capable of generating complex thoughts, actions and even self-reflection, grow out of essentially nothing? An experiment in tadpoles, in which an electronic implant was incorporated into a precursor [...]