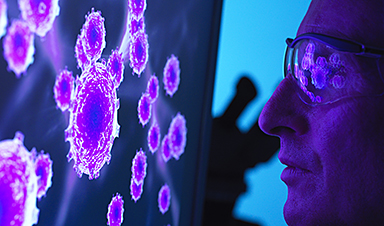

Someday, scientists believe, tiny DNA-based robots and other nanodevices will deliver medicine inside our bodies, detect the presence of deadly pathogens, and help manufacture increasingly smaller electronics.

Researchers took a big step toward that future by developing a new tool that can design much more complex DNA robots and nanodevices than were ever possible before in a fraction of the time.

In a paper published today in the journal Nature Materials, researchers from The Ohio State University—led by former engineering doctoral student Chao-Min Huang—unveiled new software they call MagicDNA.

The software helps researchers design ways to take tiny strands of DNA and combine them into complex structures with parts like rotors and hinges that can move and complete a variety of tasks, including drug delivery.

Researchers have been doing this for a number of years with slower tools with tedious manual steps, said Carlos Castro, co-author of the study and associate professor of mechanical and aerospace engineering at Ohio State.

“But now, nanodevices that may have taken us several days to design before now take us just a few minutes,” Castro said.

And now researchers can make much more complex—and useful—nanodevices.

“Previously, we could build devices with up to about six individual components and connect them with joints and hinges and try to make them execute complex motions,” said study co-author Hai-Jun Su, professor of mechanical and aerospace engineering at Ohio State.

“With this software, it is not hard to make robots or other devices with upwards of 20 components that are much easier to control. It is a huge step in our ability to design nanodevices that can perform the complex actions that we want them to do.”

The software has a variety of advantages that will help scientists design better, more helpful nanodevices and—researchers hope—shorten the time before they are in everyday use.

One advantage is that it allows researchers to carry out the entire design truly in 3-D. Earlier design tools only allowed creation in 2-D, forcing researchers to map their creations into 3-D. That meant designers couldn’t make their devices too complex.

The software also allows designers to build DNA structures “bottom up” or “top down.”

Image Credit: Uni. of Ohio

Post by Amanda Scott, NA CEO. Follow her on twitter @tantriclens

Thanks to Heinz V. Hoenen. Follow him on twitter: @HeinzVHoenen

News

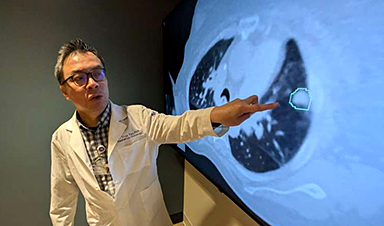

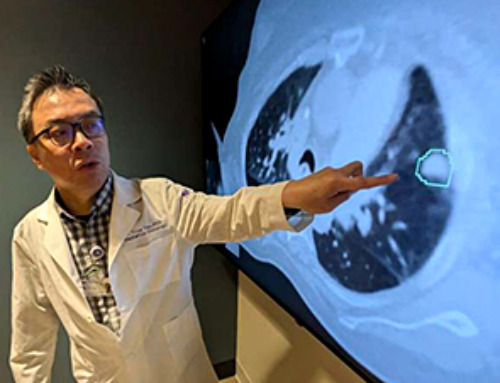

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]

Aging Spreads Through the Bloodstream

Summary: New research reveals that aging isn’t just a local cellular process—it can spread throughout the body via the bloodstream. A redox-sensitive protein called ReHMGB1, secreted by senescent cells, was found to trigger aging features [...]

AI and nanomedicine find rare biomarkers for prostrate cancer and atherosclerosis

Imagine a stadium packed with 75,000 fans, all wearing green and white jerseys—except one person in a solid green shirt. Finding that person would be tough. That's how hard it is for scientists to [...]

Are Pesticides Breeding the Next Pandemic? Experts Warn of Fungal Superbugs

Fungicides used in agriculture have been linked to an increase in resistance to antifungal drugs in both humans and animals. Fungal infections are on the rise, and two UC Davis infectious disease experts, Dr. George Thompson [...]

Scientists Crack the 500-Million-Year-Old Code That Controls Your Immune System

A collaborative team from Penn Medicine and Penn Engineering has uncovered the mathematical principles behind a 500-million-year-old protein network that determines whether foreign materials are recognized as friend or foe. How does your body [...]

Team discovers how tiny parts of cells stay organized, new insights for blocking cancer growth

A team of international researchers led by scientists at City of Hope provides the most thorough account yet of an elusive target for cancer treatment. Published in Science Advances, the study suggests a complex signaling [...]

Nanomaterials in Ophthalmology: A Review

Eye diseases are becoming more common. In 2020, over 250 million people had mild vision problems, and 295 million experienced moderate to severe ocular conditions. In response, researchers are turning to nanotechnology and nanomaterials—tools that are transforming [...]

Natural Plant Extract Removes up to 90% of Microplastics From Water

Researchers found that natural polymers derived from okra and fenugreek are highly effective at removing microplastics from water. The same sticky substances that make okra slimy and give fenugreek its gel-like texture could help [...]

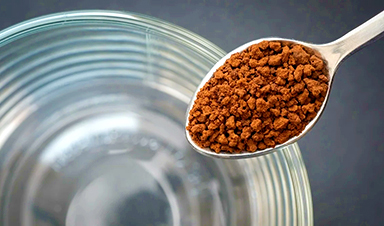

Instant coffee may damage your eyes, genetic study finds

A new genetic study shows that just one extra cup of instant coffee a day could significantly increase your risk of developing dry AMD, shedding fresh light on how our daily beverage choices may [...]

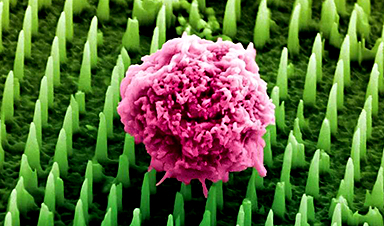

Nanoneedle patch offers painless alternative to traditional cancer biopsies

A patch containing tens of millions of microscopic nanoneedles could soon replace traditional biopsies, scientists have found. The patch offers a painless and less invasive alternative for millions of patients worldwide who undergo biopsies [...]

Small antibodies provide broad protection against SARS coronaviruses

Scientists have discovered a unique class of small antibodies that are strongly protective against a wide range of SARS coronaviruses, including SARS-CoV-1 and numerous early and recent SARS-CoV-2 variants. The unique antibodies target an [...]

Controlling This One Molecule Could Halt Alzheimer’s in Its Tracks

New research identifies the immune molecule STING as a driver of brain damage in Alzheimer’s. A new approach to Alzheimer’s disease has led to an exciting discovery that could help stop the devastating cognitive decline [...]

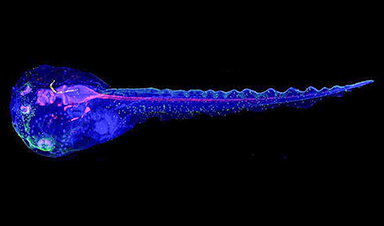

Cyborg tadpoles are helping us learn how brain development starts

How does our brain, which is capable of generating complex thoughts, actions and even self-reflection, grow out of essentially nothing? An experiment in tadpoles, in which an electronic implant was incorporated into a precursor [...]