The development of a 3D nanoprinting platform that allows the printing of polymer materials with remarkable control and nanometer spatial accuracy is the subject of a new study published in the journal Nature Communications.

Three-dimensional (3D) printing is a layer-by-layer processing technique that has found applications in a variety of fields, including tissue printing, aviation, and product engineering. To make use of the benefits of 3D printing at the micro and nanoscale, numerous approaches for downscaling 3D printing have been established during the last few decades.

Challenges Associated with 3D Nanoprinting

There has been a widespread interest in 3D printing items at the nanometer as it enables applications where specific functional features develop at the nanoscale.

Although 3D printing has modernized industrial production and development, its application to the fabrication of polymeric nanoscale materials remains a considerable issue, owing to the challenges associated with delivering the small quantities of material with high accuracy.

An effective and reliable 3D nanoprinting system must address many critical design variables, including significant spatial control over the deposition process, constant printing with few to no intermediate steps, and solvent-free material deposition to eliminate or minimize shrinking.

Schematic diagrams illustrating key steps in our 3D nanoprinting, including chemical crosslinking ink, surface modification and initiation, and the delivery of reactive ink to substrates to form 3D printed patterns.. A Structural formula of the crosslinking polymer, poly(polyethyleneglycol acrylate-co-hydroxyethylacrylate norbornene (p(PEGA-co-HEANB)), highlighting the crosslinkable pendant groups in orange. B Pre-functionalization of the surfaces with olefin-terminated SAM and initiated with the ROMP (ring-opening metathesis polymerization) catalyst Grubbs Generation III to enable Continuous Assembly of Polymers (CAP) upon delivery of p(PEGA-co-HEANB). C Schematic diagram illustrating the combined atomic force microscope (AFM) with microfluidic delivery, in realizing the CAP upon printing. The green material on the substrate shows crosslinked structures, while the blue is yet to be crosslinked. The inset scanning electron microscope image is of a FluidFM Nanopipette with a 300 nm aperture. Courtesy of Cytosurge AG. D Schematic of the resulting crosslinking formed after two layers of polymer have been deposited, showing the ability of the catalyst to continue crosslinking material. SEM scale bar: 2 µm. © Pattison, T. G. et al. (2022)

Development of a Novel 3D Nanoprinting Platform

In this work, researchers developed a 3D Nanoprinting technology that allows polymer materials to be printed with nanoscale spatial accuracy. The technique incorporates an atomic force microscope’s spatial precision, a microfluidic probe’s precise materials delivery, and solid-state continuous assembly and polymerization (CAP).

For nanoscale films and sheets, atomic force microscopy (AFM) is a useful characterization tool. This technology can provide high-resolution pictures and investigate local areas in both air (traditional AFM) and fluid (electrocatalytic AFM). The continuous assembly and polymerization (CAP) approach employs polymer crosslinkers with pendants, which generate highly crosslinked polymer sheets by surface-initiated polymerization (SIP) while retaining a high level of molecular flexibility due to the residual polymer side group activity.

Spatial Control and Precision of Polymer Materials

The researchers employed a combined AFM and microfluidic device to achieve spatial precision and accuracy in distributing macro crosslinkers (or polymeric inks) to the pre-functionalized substrate. The quantity of polymer supplied was regulated by changing the distribution parameters, such as pressure, velocity, and contact duration, in the microfluidic AFM platform. The AFM enabled precise movement by planning the polymeric ink’s path with nanoscale accuracy.

In contrast to previous efforts at 3D nanoprinting, this method may be used with a wide variety of polymeric composites, demonstrating great spatial precision and design accuracy owing to the quick assembly and polymerization after the distribution of the material. Furthermore, since the curing process happens at room temperature, the curing period is reduced and the material is more stable.

Atomic force microscopy of 3D nanoprinting following designed structures, highlighting the ability to form multilayered patterns atop of printed material. A 40 µm × 40 µm AFM topographic image of the printed cross-grids of crosslinked polymer. B Combined cursor profiles from three colored cursors indicated in A. C A 3D display of A with z scale 0–80 nm. D A 3D display of a 50 µm × 50 µm AFM topographic image of the 3D square structure with z scale 0–150 nm. E A 3D display of a 35 µm × 35 µm AFM topographic image of stacked cuboids with z scale 0–120 nm. Scale bar in A, D, and E: 10 µm. © Pattison, T. G. et al. (2022)

Important Findings of the Study

The researchers discovered that by adjusting the manufacturing settings, the breadth and height of printed materials could be readily adjusted. As the ejection rate of the polymer was almost steady under continuous reservoir pressure, the material’s height could be raised by slowing down the printing speed.

The polymeric ink was quickly cured on contact with the surface, resulting in exceptional accuracy of the 3D pattern. Because of the living nature of the linking processes, constant printing was possible without the need for additional catalysts or treatment, resulting in continuous delivery of materials in several layers. Variable print settings and complete control of the AFM-nanofluidic system were used to achieve high spatial selection and precision.

Future Perspective

In contrast to the optical-based 3D-printing techniques such as the two-photon laser process, this method allows for a broader range of applications because it can print multiple materials rather than just those containing photoconductive or photoactive substances. As a result, this technology can reduce the time necessary to manufacture compounds with photosensitive functional groups, thereby saving the overall time for 3D nanoprinting.

Future studies should concentrate on downsizing and production of overhanging components, which would need a quicker curing rate than the material delivery rate. This would enable the described 3D nanoprinting approach to be used in wearable electronics, optical systems, and biological sensors, among other applications.

News

Johns Hopkins Researchers Uncover a New Way To Kill Cancer Cells

A new study reveals that blocking ribosomal RNA production rewires cancer cell behavior and could help treat genetically unstable tumors. Researchers at the Johns Hopkins Kimmel Cancer Center and the Department of Radiation Oncology and Molecular [...]

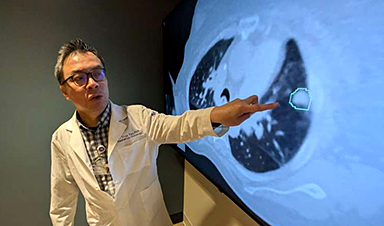

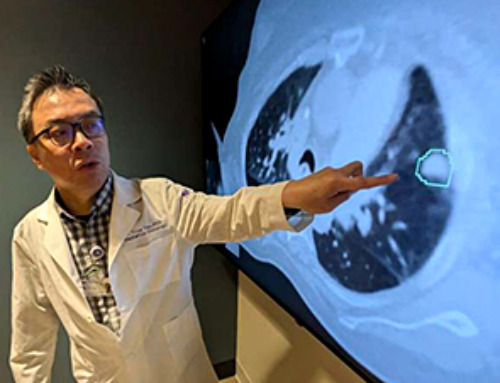

AI matches doctors in mapping lung tumors for radiation therapy

In radiation therapy, precision can save lives. Oncologists must carefully map the size and location of a tumor before delivering high-dose radiation to destroy cancer cells while sparing healthy tissue. But this process, called [...]

Scientists Finally “See” Key Protein That Controls Inflammation

Researchers used advanced microscopy to uncover important protein structures. For the first time, two important protein structures in the human body are being visualized, thanks in part to cutting-edge technology at the University of [...]

AI tool detects 9 types of dementia from a single brain scan

Mayo Clinic researchers have developed a new artificial intelligence (AI) tool that helps clinicians identify brain activity patterns linked to nine types of dementia, including Alzheimer's disease, using a single, widely available scan—a transformative [...]

Is plastic packaging putting more than just food on your plate?

New research reveals that common food packaging and utensils can shed microscopic plastics into our food, prompting urgent calls for stricter testing and updated regulations to protect public health. Beyond microplastics: The analysis intentionally [...]

Aging Spreads Through the Bloodstream

Summary: New research reveals that aging isn’t just a local cellular process—it can spread throughout the body via the bloodstream. A redox-sensitive protein called ReHMGB1, secreted by senescent cells, was found to trigger aging features [...]

AI and nanomedicine find rare biomarkers for prostrate cancer and atherosclerosis

Imagine a stadium packed with 75,000 fans, all wearing green and white jerseys—except one person in a solid green shirt. Finding that person would be tough. That's how hard it is for scientists to [...]

Are Pesticides Breeding the Next Pandemic? Experts Warn of Fungal Superbugs

Fungicides used in agriculture have been linked to an increase in resistance to antifungal drugs in both humans and animals. Fungal infections are on the rise, and two UC Davis infectious disease experts, Dr. George Thompson [...]

Scientists Crack the 500-Million-Year-Old Code That Controls Your Immune System

A collaborative team from Penn Medicine and Penn Engineering has uncovered the mathematical principles behind a 500-million-year-old protein network that determines whether foreign materials are recognized as friend or foe. How does your body [...]

Team discovers how tiny parts of cells stay organized, new insights for blocking cancer growth

A team of international researchers led by scientists at City of Hope provides the most thorough account yet of an elusive target for cancer treatment. Published in Science Advances, the study suggests a complex signaling [...]

Nanomaterials in Ophthalmology: A Review

Eye diseases are becoming more common. In 2020, over 250 million people had mild vision problems, and 295 million experienced moderate to severe ocular conditions. In response, researchers are turning to nanotechnology and nanomaterials—tools that are transforming [...]

Natural Plant Extract Removes up to 90% of Microplastics From Water

Researchers found that natural polymers derived from okra and fenugreek are highly effective at removing microplastics from water. The same sticky substances that make okra slimy and give fenugreek its gel-like texture could help [...]

Instant coffee may damage your eyes, genetic study finds

A new genetic study shows that just one extra cup of instant coffee a day could significantly increase your risk of developing dry AMD, shedding fresh light on how our daily beverage choices may [...]

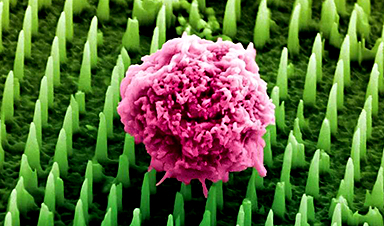

Nanoneedle patch offers painless alternative to traditional cancer biopsies

A patch containing tens of millions of microscopic nanoneedles could soon replace traditional biopsies, scientists have found. The patch offers a painless and less invasive alternative for millions of patients worldwide who undergo biopsies [...]

Small antibodies provide broad protection against SARS coronaviruses

Scientists have discovered a unique class of small antibodies that are strongly protective against a wide range of SARS coronaviruses, including SARS-CoV-1 and numerous early and recent SARS-CoV-2 variants. The unique antibodies target an [...]

Controlling This One Molecule Could Halt Alzheimer’s in Its Tracks

New research identifies the immune molecule STING as a driver of brain damage in Alzheimer’s. A new approach to Alzheimer’s disease has led to an exciting discovery that could help stop the devastating cognitive decline [...]