From an article by

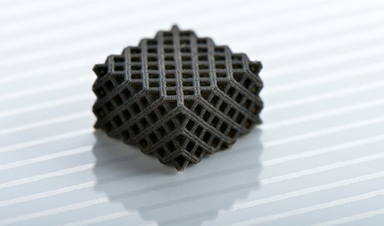

You would be hard pressed today to find a technology more versatile than 3D printing. Making significant impacts that span nearly every industry worldwide, whether you are considering dental 3D printers, titanium spinal implants, luxury car components, or futuristic buildings, we’re witnessing many changes we just never expected. But 3D printing also offers versatility in materials, from metal to PEEK—as well as shapes and sizes and properties. There is a machine for every job it would seem, from the macro- to the micro-level. And while we certainly see innovations emerging from the tiny to the enormous, there is a great deal of interest in 3D printing at the super tiny level—as in nano.

Smaller than tiny and tinier than micro, the nanoscale operates at one billionth of a meter or better yet, as 25,400,000 nanometers in an inch. And this is where the hearts of many researchers lie as they work diligently, innovating in the realm of materials science and 3D printing. At Virginia Tech, however, researchers are not content with operating with nanos. They want to see if they can scale them right back up as well and still retain the use of their special qualities.

![]()

Image Credit: Virginia Tech News

Recent News

New Research Reveals That Your Sense of Smell May Be Smarter Than You Think

A new study published in the Journal of Neuroscience indicates that the sense of smell is significantly influenced by cues from other senses, whereas the senses of sight and hearing are [...]

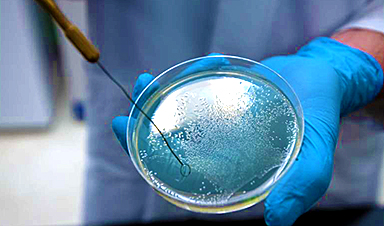

Deadly bacteria show thirst for human blood: the phenomenon of bacterial vampirism

Some of the world's deadliest bacteria seek out and feed on human blood, a newly-discovered phenomenon researchers are calling "bacterial vampirism." A team led by Washington State University researchers [...]

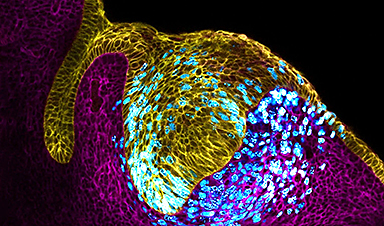

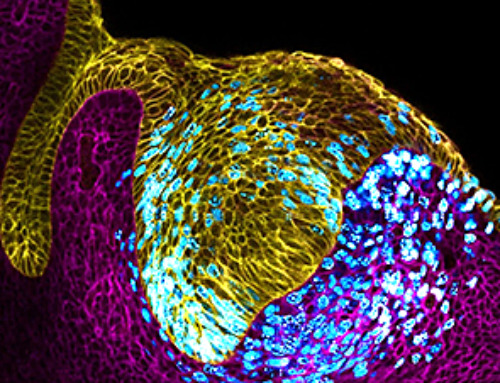

Organ Architects: The Remarkable Cells Shaping Our Development

Finding your way through the winding streets of certain cities can be a real challenge without a map. To orient ourselves, we rely on a variety of information, including [...]

Novel hydrogel removes microplastics from water

Microplastics pose a great threat to human health. These tiny plastic debris can enter our bodies through the water we drink and increase the risk of illnesses. They are [...]

Researchers Discover New Origin of Deep Brain Waves

Understanding hippocampal activity could improve sleep and cognition therapies. Researchers from the University of California, Irvine’s biomedical engineering department have discovered a new origin for two essential brain waves—slow waves and [...]

The Lifelong Cost of Surviving COVID: Scientists Uncover Long-Term Effects

Many of the individuals released to long-term acute care facilities suffered from conditions that lasted for over a year. Researchers at UC San Francisco studied COVID-19 patients in the United States who survived [...]

Previously Unknown Rogue Immune Key to Chronic Viral Infections Discovered

Scientists discovered a previously unidentified rogue immune cell linked to poor antibody responses in chronic viral infections. Australian researchers have discovered a previously unknown rogue immune cell that can [...]

Nature’s Betrayal: Unmasking Lead Lurking in Herbal Medicine

A case of lead poisoning due to Ayurvedic medicine use demonstrates the importance of patient history in diagnosis and the need for public health collaboration to prevent similar risks. [...]

Frozen in Time: How a DNA Anomaly Misled Scientists for Centuries

An enormous meteor spelled doom for most dinosaurs 65 million years ago. But not all. In the aftermath of the extinction event, birds — technically dinosaurs themselves — flourished. [...]

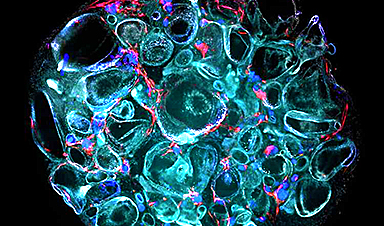

‘Mini kidneys’ reveal new insights into metabolic defects in polycystic kidney disease

Scientists at Nanyang Technological University, Singapore (NTU Singapore) have successfully grown 'mini kidneys' in the lab and grafted them into live mice, revealing new insights into the metabolic defects [...]

Decoding the Origin of Life: Scientists Solve Early Earth RNA Puzzle

Recent research illustrates how RNA molecules’ chemical characteristics might have played a crucial role in the development of complex life forms. How did complex life manage to evolve on [...]

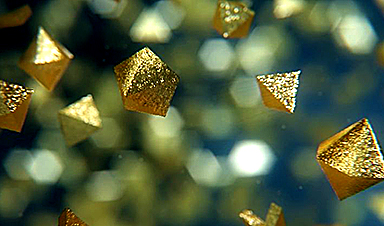

Improving infectious disease testing with gold nanoparticles

By harnessing the power of composite polymer particles adorned with gold nanoparticles, a group of researchers have delivered a more accurate means of testing for infectious diseases. Details of their [...]

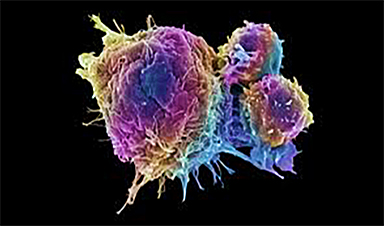

New micromaterial releases nanoparticles that selectively destroy cancer cells

Researchers have developed micromaterials made up only of proteins, capable of delivering over an extended period of time nanoparticles that attack specific cancer cells and destroy them. The micromaterials [...]

Alzheimer’s Breakthrough: Scientists Make Revolutionary Leap

Dementia is a major health issue worldwide in the 21st century, impacting over 50 million people globally. This figure is expected to soar to 152 million by 2050, as [...]

How small RNA molecules regulate viral infections of bacteria

Viruses need hosts. Whether it's measles, the flu or coronavirus, viral pathogens cannot multiply or infect other organisms without the assistance of their hosts' cellular infrastructure. However, humans are [...]

Computer scientists discover gap in the latest security mechanisms used by some chips

Over the past few years, hardware manufacturers have developed technologies that ought to make it possible for companies and governmental organizations to process sensitive data securely using shared cloud [...]

Microplastics Are a Big Problem, a New Film Warns

It’s been more than five decades since Dustin Hoffman’s character in “The Graduate” was offered a kernel of wisdom about the path to prosperity. “Plastics,” he’s told by Mr. McGuire, [...]

The Precarious Asymmetries of Human-AI Relationships

KEY POINTS Human-AI interactions are currently asymmetrical, lacking continuity and depth. AI evolution may lead to more sustained, contextually rich user relationships. Balancing asymmetry and connection requires design advocacy [...]

Vaping’s Hidden Dangers: New Study Links E-Cigarettes to DNA Changes

A new study led by researchers from University College London (UCL) and the University of Innsbruck reveals that individuals who use e-cigarettes, despite having a limited history of smoking, undergo similar changes in DNA within [...]

The Iron Twist: The Unexpected Driver of Long COVID

Iron levels and inflammation after COVID-19 infection are linked to long COVID, with research indicating that early intervention in iron regulation could mitigate long-term symptoms. Problems with iron levels in the [...]

Chemists develop method to confirm mRNA vaccine stability

University at Albany researchers at the RNA Institute have developed a new method to test COVID-19 vaccine integrity that could allow anyone with basic skills in vaccine handling to [...]

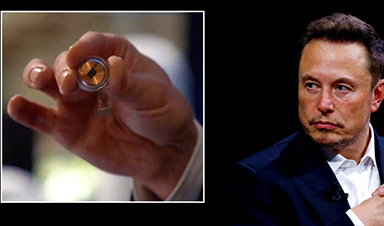

A New Cognitive Compartmentalization with Neural Implants

KEY POINTS Neuralink's demo introduces "cognitive compartmentalization," enabling simultaneous cognitive tasks. This signifies a potential expansion in human cognitive abilities, enhancing multitasking and creativity. Raises concerns about cognitive overload [...]

Global Warming and Plastic Pollution Are Inextricably Trapped in a “Vicious Circle”

Typically viewed as unrelated problems, global warming and plastic pollution are instead inextricably trapped in a “vicious circle” where one feeds the other, researchers in Sweden report in Nature Communications. [...]

Primordial Fuel: Uncovering Hydrogen’s Role at the Origin of Life

Hydrogen gas, dubbed the energy of the future, has been providing energy since 4 billion years ago. A recent study reveals how hydrogen gas, often touted as the energy [...]

COVID-19 Had a Much Greater Impact on Life Expectancy Than Previously Thought

A recent study published in The Lancet never-before-seen unprecedented details on the exceptionally high death rates due to the COVID-19 pandemic both within nations and internationally. Regions including Mexico City, Peru, and Bolivia [...]

Molecular Majesty: This Is How the Body’s Building Blocks Are Made

Human cells contain ribosomes, a complex machine that produces proteins for the rest of the body. Now the researchers have come closer to understanding how the ribosome works. “It [...]

U.S. issue warning about return of potentially deadly virus

The American South has been under constant duress from extreme weather events spurred by rising global temperatures, but the region could face a different kind of threat that it hasn't experienced [...]

Climate Change Ignites Global Infectious Disease Alarm

Experts highlight the connection between climate change and infectious diseases, urging medical professionals to prepare for new disease patterns and advocate for climate action. A team of infectious diseases [...]

How Lignin Nanoparticles Enhance UV Protection in Sunscreen Formulas

The innovative realm of cosmetic science has recently spotlighted lignin nanoparticles (LNPs) for their exceptional potential in fortifying sun protection measures within skincare products. These nanoparticles are celebrated for [...]

mRNA lipid nanoparticles for next-generation oral cancer tumor suppressor therapy

A study aiming to develop a lipid nanoparticles (LNP) platform for treating oral squamous cell carcinoma (OSCC) utilizing p53 mRNA was presented at the 102nd General Session of the IADR, [...]

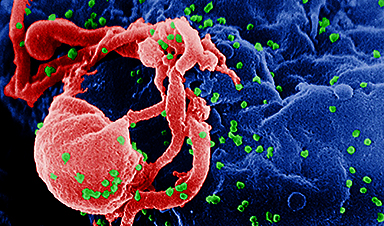

Scientists have literally cut HIV out of cells

HIV has been completely eliminated from cells in a laboratory, raising hopes of a future cure. Researchers completed the revolutionary task by using a gene-editing tool known as Crispr-Cas, which won [...]

Common Medication Could Save Half a Million Lives Each Year – So Why Isn’t It?

A recent study conducted by scientists at the University of Southern California sheds light on the reasons why children are not receiving an affordable and effective diarrhea treatment. Medical [...]

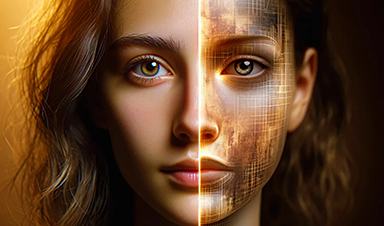

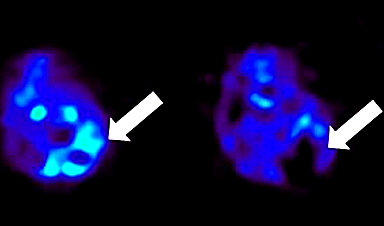

X Marks the Spot: AI’s Treasure Maps Lead to Early Disease Detection

Medical diagnostics expert, doctor’s assistant, and cartographer are all fair titles for an artificial intelligence model developed by researchers at the Beckman Institute for Advanced Science and Technology. Their [...]

Scientists Discover Method To Identify Alzheimer’s Disease Before It Progresses to Dementia

Researchers at Aarhus University have discovered a method to identify Alzheimer’s disease before it progresses to dementia, potentially opening up new avenues for treatment. A groundbreaking study could pave [...]

Startling Discovery: COVID-19 Virus Can Stay in the Body More Than a Year After Infection

The COVID-19 virus can persist in the blood and tissue of patients for more than a year after the acute phase of the illness has ended, according to new research from UC [...]

New bioengineered protein design shows promise in fighting COVID-19

In the wake of the COVID-19 pandemic, scientists have been racing to develop effective treatments and preventatives against the virus. A recent scientific breakthrough has emerged from the work [...]

Sugar-coated gold nanoparticles can quickly eliminate bacterial infections, no antibiotics required

If left to their own devices, bacteria on our teeth or wounded skin can encase themselves in a slimy scaffolding, turning into what is called biofilm. These bacteria wreak [...]

Liquid Lightning: Nanotechnology Unlocks New Energy

EPFL researchers have discovered that nanoscale devices harnessing the hydroelectric effect can harvest electricity from the evaporation of fluids with higher ion concentrations than purified water, revealing a vast untapped energy [...]

Unmasking the Illusion: AI-Generated Faces Challenge Perceptions

Research shows survey participants duped by AI-generated images nearly 40 percent of the time. If you recently had trouble figuring out if an image of a person is real [...]

New Discovery Reveals How Cells Defend Themselves During Stressful Situations

Stress granules play a crucial role in the stress response, arising from the aggregation of non-translating mRNAs and proteins. Although significant knowledge exists about stress granules, the mechanisms behind [...]

Scientists use a new type of nanoparticle that can both deliver vaccines and act as an adjuvant

Many vaccines, including vaccines for hepatitis B and whooping cough, consist of fragments of viral or bacterial proteins. These vaccines often include other molecules called adjuvants, which help to [...]

Not Science Fiction: How Optical Neural Networks Are Revolutionizing AI

A novel architecture for optical neural networks utilizes wavefront shaping to precisely manipulate the travel of ultrashort pulses through multimode fibers, enabling nonlinear optical computation. Present-day artificial intelligence systems [...]

Turning skin cells into limb cells sets the stage for regenerative therapy

In a collaborative study, researchers from Kyushu University and Harvard Medical School have identified proteins that can turn or “reprogram” fibroblasts — the most commonly found cells in skin [...]

AI reveals prostate cancer is not just one disease

Artificial Intelligence has helped scientists reveal a new form of aggressive prostate cancer, which could revolutionise how the disease is diagnosed and treated in the future. A Cancer Research [...]

New Study Finds That Persistent COVID-19 Infections Are Surprisingly Common

Recent research conducted by the University of Oxford has found that a high proportion of SARS-CoV-2 infections in the general population lead to persistent infections lasting a month or more. The findings have [...]

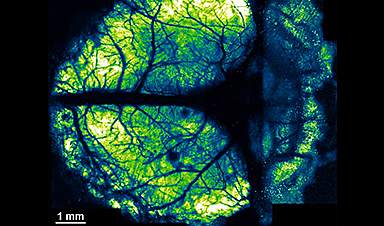

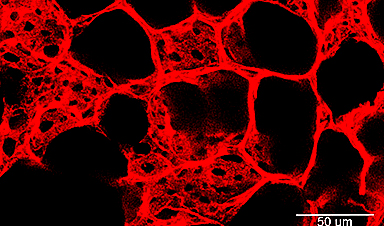

Innovative nanosheet method revolutionizes brain imaging for multi-scale and long-term studies

The human brain has billions of neurons. Working together, they enable higher-order brain functions such as cognition and complex behaviors. To study these higher-order brain functions, it is important [...]

Scientists Have Discovered a Potential Universal Antivenom

Scientists at Scripps Research identified antibodies that protect against a host of lethal snake venoms. Scripps Research scientists have developed an antibody that can block the effects of lethal [...]

Scientists discover the human brain is even more powerful than we thought

The human brain could be far more powerful than we ever imagined, scientists have discovered. Researchers have identified cell messaging which have never been uncovered before, which suggests our brains are capable of [...]

Concerning – Bird Flu Has Evolved To Spread to Marine Mammals

A study from the University of California, Davis, and the National Institute of Agricultural Technology (INTA) in Argentina reveals that the highly contagious H5N1 avian influenza virus has evolved to transmit among [...]

AI technique ‘decodes’ microscope images, overcoming fundamental limit

Atomic force microscopy, or AFM, is a widely used technique that can quantitatively map material surfaces in three dimensions, but its accuracy is limited by the size of the [...]

Transforming Cancer Treatment: CRISPR Technology Unveils a New Path

New technology using CRISPR to enhance the immune system’s ability to detect cancer cells has been created, potentially paving the way for innovative cancer treatment methods. Major histocompatibility complex [...]

Scientists May Have Cracked the “Aging Process” in Species

A new study led by the University of Kansas might resolve a mystery in the “aging process” in species — or, how a species’ risk of going extinct changes after that species appears [...]

Scientists Solve Decades-Old Mystery of How Predatory Bacteria Recognizes Prey

A decades-old mystery of how natural antimicrobial predatory bacteria are able to recognize and kill other bacteria may have been solved, according to new research. In a study published [...]

A Sprinkle of Gold Dust Could Help Reverse Symptoms of Parkinson’s Disease

Scientists are investigating whether an oral drug sprinkled with gold nanoparticles could one day treat neurodegenerative diseases like Parkinson's and multiple sclerosis. The experimental medicine, called CNM-Au8, has now [...]

Scientists closer to finding quantum gravity theory after measuring gravity on microscopic level

Scientists are a step closer to unraveling the mysterious forces of the universe after working out how to measure gravity on a microscopic level. Experts have never fully understood [...]

Nanoparticles Repair Lung Tissue Damaged From Flu or COVID-19

Recent research reveals a breakthrough in lung repair, showing how delivering VEGFA via lipid nanoparticles can significantly repair damaged blood vessels, akin to plumbing repairs. This method, validated in [...]

Evading Bacterial Resistance: Scientists Develop Groundbreaking New Antibiotic

Researchers from the University of Illinois Chicago and Harvard University have created an antibiotic that may provide medicine a new tool to combat bacteria resistant to drugs and the illnesses they trigger. The [...]

Elon Musk says first brain chip human can move a mouse around screen by thinking

Elon Musk has claimed the first human patient implanted with his wireless Neuralink brain chip can move a computer cursor ‘just by thinking’. ‘Progress is good, and the patient seems to [...]

Largest ever global study of COVID vaccines finds small but real link to neurological, blood, heart-related conditions

Vaccines that protect against severe illness, death and lingering long Covid symptoms from a coronavirus infection were linked to small increases in neurological, blood, and heart-related conditions in the largest global vaccine [...]

Scientists Propose “Radically Different” New Way of Looking at Parkinson’s Disease

Scientists propose a new model for classifying Parkinson’s. The complexity of Parkinson’s disease poses significant challenges in developing effective treatments. This complexity stems from various causes, including genetics and [...]

Nanomaterial with potential could be developed without risk to human health

A revolutionary nanomaterial with huge potential to tackle multiple global challenges could be developed further without acute risk to human health, research suggests. The study is published in the journal Nature Nanotechnology. [...]

Headaches, Memory Problems, and Fatigue – How COVID-19 Affects the Brain

Neurological symptoms are apparently not a result of SARS-CoV-2 infection of the brain. Scientists still are not sure how neurological symptoms arise in COVID-19. Is it because SARS-CoV-2 infects the brain? Or [...]

An Antibiotic You Inhale Can Deliver Medication Deep Into the Lungs

We’ve all been more aware of lung health since Covid-19. However, for people with asthma and chronic obstructive pulmonary disease (COPD), dealing with lung problems is a lifelong struggle. [...]

Novel hydroxyapatite-targeting nanodrug may be a paradigm shift for cancer treatment

A multidisciplinary research team at Vanderbilt University and Vanderbilt University Medical Center has discovered a new way to kill a tumor by disrupting its acidic "microenvironment" without harming normal [...]

Which Virus Will Cause the Next Global Pandemic? Scientists Discover New Disease X Clues

Understanding the ancestry of virus families may assist researchers in pinpointing which variants possess the potential to become Disease X, the elusive pathogen responsible for the next worldwide pandemic. A study [...]

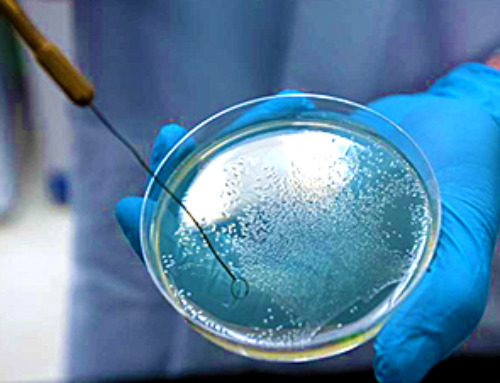

Vibrio natriegens: Low-cost microbe could speed biological discovery

Cornell University researchers have created a new version of a microbe to compete economically with E. coli—a bacteria commonly used as a research tool due to its ability to [...]

Risk of Existential Catastrophe: There Is No Proof That AI Can Be Controlled

Highlighting the absence of evidence for the controllability of AI, Dr. Yampolskiy warns of the existential risks involved and advocates for a cautious approach to AI development, with a [...]

Nanofiber-coated cotton bandages fight infection and speed healing

An interdisciplinary team of Cornell researchers has identified an innovative way to harness the antioxidant and antibacterial properties of the botanical compound lawsone to make nanofiber-coated cotton bandages that [...]

Ancient Brain Region Discovered To Be More Important Than Previously Thought

Researchers from the Netherlands Institute for Neuroscience found that the superior colliculus, a brain region preserved throughout evolution, plays a more vital role in vision than previously believed. When [...]

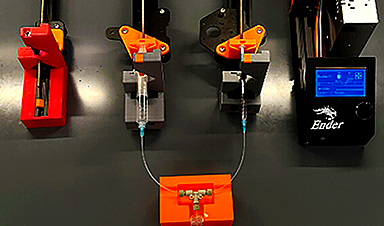

Nanomedicine advancement shows potential for personalized point-of-care therapeutics

Stefan Wilhelm, an associate professor in the Stephenson School of Biomedical Engineering at the University of Oklahoma, and several students in his Biomedical Nano-Engineering Lab have recently published an article in [...]

What Happens When Machine Learning Goes Too Far?

Every piece of fiction carries a kernel of truth, and now is about the time to get a step ahead of sci-fi dystopias and determine what the risk in [...]

Future of Health: Predicting Disease With Retinal Imaging and Genetics

Mass Eye and Ear physician-researchers show that retinal imaging can help predict a person’s risk of developing ocular, neuropsychiatric, cardiac, metabolic, and pulmonary diseases. The team also identified genetic [...]

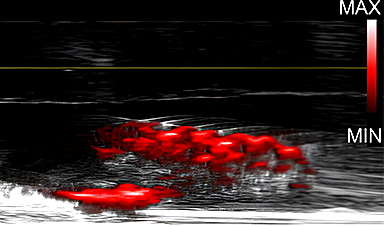

Artificially intelligent software provides a detailed look at jets of plasma used to treat cancer

Artificially intelligent software has been developed to enhance medical treatments that use jets of electrified gas known as plasma. The computer code predicts the chemicals emitted by plasma devices, [...]

Physicists Unlock Quantum Immortality With Revolutionary Time Crystal

Researchers have successfully extended the lifespan of time crystals, confirming a theoretical concept proposed by Frank Wilczek. This marks a significant step forward in quantum physics. A team from [...]

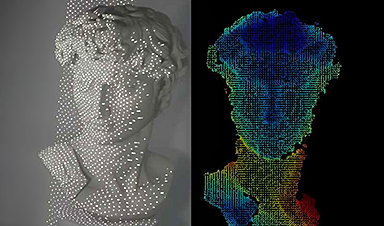

A sleeker facial recognition technology tested on Michelangelo’s David

Many people are familiar with facial recognition systems that unlock smartphones and game systems or allow access to our bank accounts online. But the current technology can require boxy [...]

Leave A Comment